China has established itself as a global leader in manufacturing, and the riveting machine industry is no exception. As the demand for efficient and precise fastening solutions continues to grow across various sectors, choosing the right riveting machine manufacturer has become crucial for businesses worldwide. This article explores the top 10 riveting machine manufacturers in China, providing valuable insights to help you make an informed decision.

Overview

The Chinese riveting machine manufacturing industry has seen substantial growth, fueled by rising demand from the automotive, aerospace, and electronics sectors. By 2025, the industry’s value is projected to reach around $3.5 billion, with an annual growth rate of 6.8%. Chinese manufacturers have secured a competitive advantage by integrating advanced technology with cost-effective production methods, appealing to both domestic and international markets.

Top 10 riveting machine Manufacturers in China

1. Wuhan Rivet Machinery Co., Ltd.

Established in 2002, Wuhan Rivet Machinery has become a leading provider of riveting machines and equipment in China. The company specializes in designing and manufacturing reliable and economical riveting products for various industries, including automotive, aerospace, and hardware.

Business Type: Manufacturer/Factory

Headquarters: Wuhan, Hubei, China

Main Markets: Over 50 countries and regions, including US, UK, Japan, France, Italy, Germany, India, Russia, Poland, Brazil, Argentina, and Malaysia

Establishment Year: 2002

Certificates/Awards: ISO9001, European CE standards, “High and New-tech Enterprise” award from the National Government in 2012

Wuhan Rivet Machinery, a leader in the riveting machine industry, offers over 100 diverse assembly equipment solutions, including desk-top, vertical, hydraulic, and CNC riveting machines. Their partnership with Wuhan University in 2012 established China’s only national riveting technology research lab, leading to innovative products like the third-generation Wheel-hub Bearing Intelligent riveting machine. The company’s commitment to quality and service is evident through their free one-year warranty and custom support, while their advanced manufacturing capabilities and strong R&D focus, resulting in 13 large-scale projects and 11 National Patents by 2012, continue to solidify their global position.

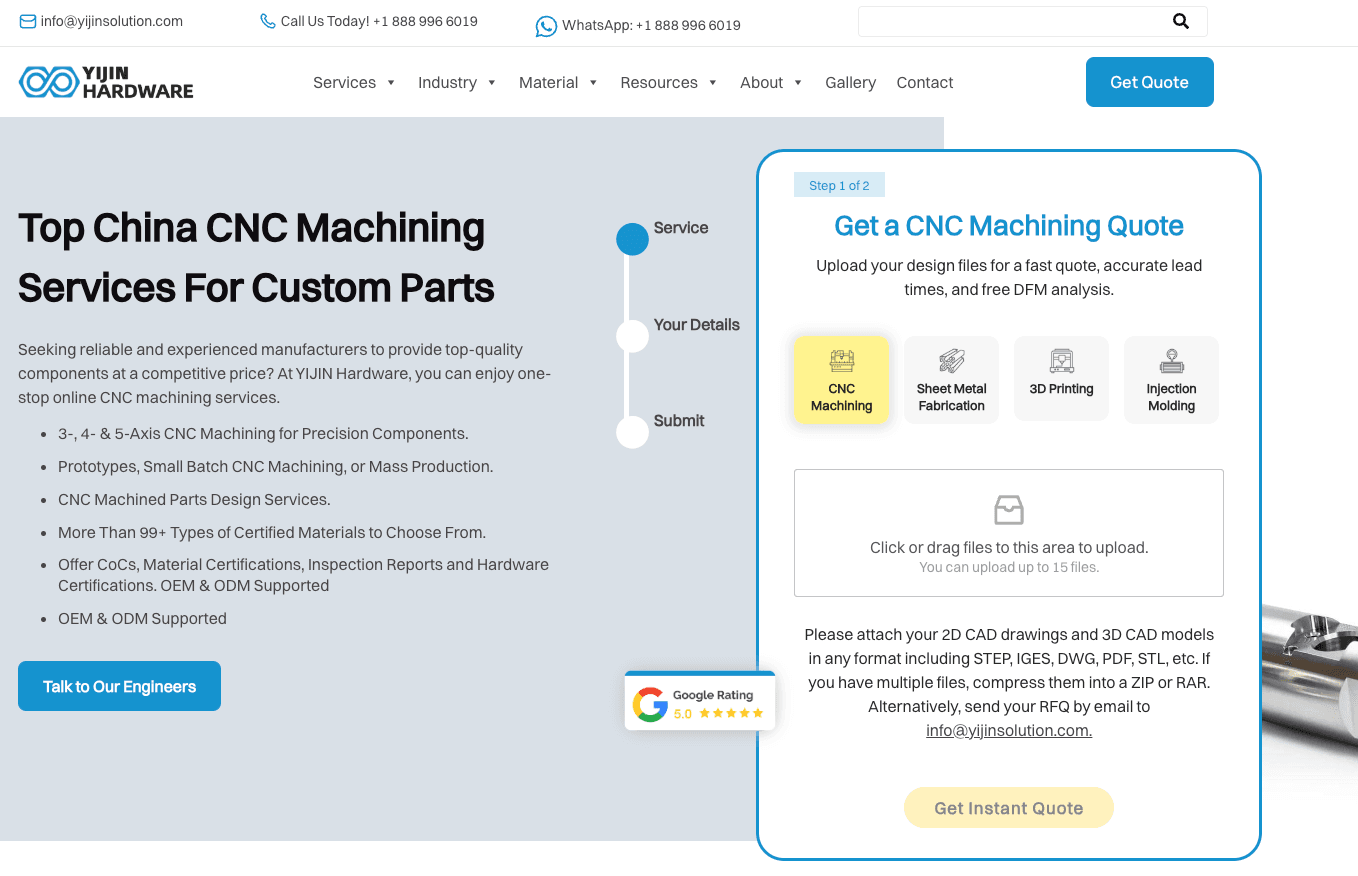

2. Shenzhen Yijin Hardware Co., Ltd.

Shenzhen Yijin Hardware Co., Ltd. is a prominent manufacturer specializing in precision hardware parts, including a diverse range of riveting machines.

Business Type: Manufacturer

Headquarters: Shenzhen, Guangdong, China

Main Markets: Switzerland, France, Italy, Thailand, United Kingdom, United States

Establishment Year: 2004

Certificates/Awards: ISO 9001:2015 certified

Shenzhen Yijin Hardware is a leading provider of high-quality riveting solutions with over 20 years of experience in precision hardware manufacturing. Their diverse product range includes pneumatic, hydraulic, and automatic riveting machines designed for various industrial applications. The company prioritizes research and development, supported by a skilled team specializing in CNC machining and riveting technologies, and operates an advanced manufacturing facility of 5,000-10,000 square meters with 10 production lines featuring cutting-edge machinery.

Yijin’s commitment to quality and innovation has made them a trusted partner for precision fastening solutions. With a strong export orientation (61-70% export percentage) and the capability to provide customized riveting solutions, they have established themselves as a significant player in the global riveting machine market.

3. PennEngineering Fastening Technologies (China) Co., Ltd.

PennEngineering Fastening Technologies (China) Co., Ltd. is a subsidiary of PennEngineering, a global leader in the fastening industry since 1942.

Business Type: Manufacturer

Headquarters: Kunshan, Jiangsu, China

Main Markets: Global, with a strong presence in Asia

Establishment Year: 1942

Certificates/Awards: Multiple industry certifications (specific details not provided in the search results)

PennEngineering Fastening Technologies (China) Co., Ltd. specializes in manufacturing high-strength components and fasteners, including riveting solutions for the global market. As part of its strategy to serve Asia, the company offers the PEMSERTER® series riveting presses and automated systems, widely utilized in the automotive and electronics industries.

The company’s dedication to innovation and quality is evident in its controlled, multi-process production techniques that blend forming and precision machining. This capability enables PennEngineering to provide competitively priced products without sacrificing quality.

With a strong global presence and local manufacturing in China, PennEngineering Fastening Technologies positions itself as a key player in the Chinese riveting machine market, catering to customers seeking high-quality and innovative fastening solutions.

4. Atlas Copco (China) Investment Co., Ltd.

Atlas Copco (China) Investment Co., Ltd. is the Chinese subsidiary of Atlas Copco, a Swedish multinational industrial company founded in 1873.

Business Type: Manufacturer and Service Provider

Headquarters: Shanghai, China

Main Markets: Global, with a strong presence in China and Asia-Pacific

Establishment Year: 1873

Certificates/Awards: ISO 9001, ISO 14001, OHSAS 18001

Atlas Copco, through its Henrob brand, has emerged as a key player in China’s riveting machine industry, focusing on self-piercing riveting technology for sectors like automotive manufacturing. The company offers advanced systems and robotic solutions that cater to the automotive industry’s need for lightweight construction, providing high-strength joining for mixed materials such as aluminum, high-strength steel, and composites.

A significant advantage of Atlas Copco’s riveting solutions is their advanced process monitoring and quality control systems, which ensure consistent, high-quality results crucial for safety-critical applications. Their commitment to innovation is demonstrated by ongoing technology development to enhance riveting processes. With a robust local presence in China and extensive global expertise, Atlas Copco positions itself as a trusted partner for businesses seeking world-class riveting solutions supported by local assistance.

5. BalTec Machinery (Shanghai) Co., Ltd.

BalTec Machinery (Shanghai) Co., Ltd. is the Chinese arm of BalTec, a Swiss company renowned for its innovative riveting solutions.

Business Type: Manufacturer

Headquarters: Shanghai, China

Main Markets: China, Asia-Pacific, and global markets

Certificates/Awards: ISO 9001:2015

BalTec Machinery (Shanghai) Co., Ltd. is a leading provider of high-precision riveting solutions in China, specializing in radial and orbital riveting machines, as well as roller forming machines for key industries such as automotive, medical devices, and consumer electronics. Its focus on meeting the stringent quality and safety standards of the medical and automotive sectors has resulted in a versatile product range that includes both standard and customized solutions tailored to specific production needs.

With a commitment to quality and precision, BalTec has established itself as a preferred choice for manufacturers seeking reliable and efficient riveting solutions. By combining Swiss engineering excellence with local manufacturing in China, the company ensures exceptional support and service, reinforcing its strong position in the Chinese riveting machine market.

6. Wuxi Yuke Environmental Science & Technology Co. Ltd

Wuxi Yuke Environmental Science & Technology Co. Ltd, established in 2007, has rapidly grown to become a significant player in the Chinese riveting machine industry.

Business Type: Manufacturer

Headquarters: Wuxi, Jiangsu, China

Main Markets: Domestic Chinese market and international exports

Establishment Year: 2007

Certificates/Awards: ISO 9001:2015 certified

Wuxi Yuke has made significant strides in the riveting machine industry through a focus on innovation and continuous improvement. Specializing in the design and manufacture of blind rivet and pneumatic riveting machines, the company caters to diverse industrial applications while emphasizing research and development to consistently introduce advanced riveting technologies. Recognized for their reliability, efficiency, and user-friendly design, Wuxi Yuke’s products appeal to both small-scale manufacturers and large industrial operations.

With advanced production lines and robust quality control systems, Wuxi Yuke ensures all products meet stringent quality standards, backed by its ISO 9001:2015 certification. The company’s success is fueled by a customer-centric approach, competitive pricing, and strong after-sales service. As Wuxi Yuke expands its product range and market presence, it is well-positioned to become a more prominent player in the global riveting machine market.

7. AGME Riveting Equipment (Shanghai) Co., Ltd.

AGME Riveting Equipment (Shanghai) Co., Ltd. is the Chinese subsidiary of AGME, a Spanish company with a rich history in manufacturing riveting solutions.

Business Type: Manufacturer

Headquarters: Shanghai, China

Main Markets: China, Asia-Pacific, and global markets

Certificates/Awards: ISO 9001, ISO 14001

AGME Riveting Equipment (Shanghai) Co., Ltd. is a leading provider of advanced riveting solutions in China, specializing in orbital and radial riveting machines, as well as custom systems for the automotive, electronics, and aerospace industries. A key strength of AGME lies in its integration of Industry 4.0 technologies, which enhance process control, real-time monitoring, and data analytics, enabling manufacturers to optimize operations and improve quality control.

The company’s versatile product range includes both standard machines and fully customized solutions tailored to specific production needs. This flexibility, combined with a commitment to innovation and quality, positions AGME as a preferred choice for manufacturers seeking cutting-edge technology. With its Spanish heritage and local manufacturing in China, AGME effectively blends European engineering expertise with local support, establishing a strong presence in the Chinese market, particularly among those pursuing advanced, Industry 4.0-ready solutions.

8. Bollhoff (China) Fasteners Co., Ltd.

Bollhoff (China) Fasteners Co., Ltd. is the Chinese subsidiary of Bollhoff Group, a German company with a long history in fastening technology dating back to 1877.

Business Type: Manufacturer and Service Provider

Headquarters: Wuxi, Jiangsu, China

Main Markets: China, Asia-Pacific, and global markets

Establishment Year: 1877

Certificates/Awards: ISO 9001, IATF 16949, ISO 14001

Bollhoff (China) Fasteners Co., Ltd. is a leading provider of high-quality fastening and assembly systems, primarily serving the automotive and aerospace industries. The company offers innovative riveting solutions, including its proprietary RIVSET® self-piercing riveting systems and ONSERT® technology, which are essential for lightweight construction and joining mixed materials like advanced high-strength steels, aluminum alloys, and composites.

A key strength of Bollhoff lies in its focus on lightweight construction solutions, making it a valuable partner for manufacturers looking to reduce vehicle weight while ensuring structural integrity. With significant investments in research and development, the company drives continuous innovation and holds numerous patents that enhance its position in the fastening industry.

Combining German engineering heritage with a strong local presence in China, Bollhoff merges world-class technology with local manufacturing and support. This approach establishes a significant foothold in the Chinese market, particularly among automotive and aerospace manufacturers seeking advanced fastening solutions.

9. Zhang Nian Fa Machinery Co., Ltd.

Zhang Nian Fa Machinery Co., Ltd. is a Taiwanese company with manufacturing facilities in mainland China, specializing in riveting machines for various applications.

Business Type: Manufacturer

Headquarters: Taiwan, with manufacturing facilities in mainland China

Main Markets: China, Southeast Asia, and global exports

Certificates/Awards: ISO 9001 (assumed, but not explicitly stated in the search results)

Zhang Nian Fa Machinery Co., Ltd. is a key player in the Chinese riveting machine market, offering a diverse range of solutions for industries such as furniture and automotive. The company specializes in pneumatic, hydraulic, and automatic feed riveting machines, providing customized solutions tailored to clients’ specific needs, which has made it a preferred choice for manufacturers seeking specialized options.

Recognized for reliability, efficiency, and cost-effectiveness, Zhang Nian Fa continuously enhances its manufacturing processes and product designs to meet market demands. Supported by modern machinery and robust quality control systems, the company ensures consistent high quality across its product range.

With its Taiwanese heritage and manufacturing presence in mainland China, Zhang Nian Fa effectively combines Taiwanese engineering expertise with the cost advantages of local production. This unique positioning has solidified its foothold in the Chinese market, particularly among manufacturers looking for reliable and customized solutions.

10. Anyang San Xing Machinery Industry Co., Ltd.

Anyang San Xing Machinery Industry Co., Ltd., founded in 1993, has emerged as a significant player in the Chinese riveting machine market, with a focus on hydraulic riveting solutions.

Business Type: Manufacturer

Headquarters: Anyang, Henan, China

Main Markets: Domestic Chinese market and international exports

Establishment Year: 1993

Certificates/Awards: Multiple patents for innovative riveting technologies (specific details not provided in the search results)

San Xing Machinery is a leading provider of hydraulic riveting machines and production lines in China, leveraging its extensive industry experience to develop deep expertise in riveting technologies, particularly hydraulic systems. A key strength of San Xing is its commitment to innovation, demonstrated by multiple patents for advanced riveting technologies that enhance efficiency, precision, and reliability.

The product range includes various hydraulic riveting machines and complete production lines tailored to the automotive sector and other industrial needs. Recognized for their robust construction and high performance, San Xing’s machines serve a wide array of applications, making the company a valuable partner for manufacturers seeking reliable and efficient equipment.

San Xing’s success is driven by its technological innovation and customer-centric approach. By offering both standard and customized riveting solutions, the company is well-positioned to maintain a strong presence in the Chinese riveting machine market as it continues to innovate and expand its offerings.

Comparison of Riveting Machine Manufacturers

| Manufacturer | Key Products | Price Range | Specialties |

|---|---|---|---|

| Wuhan Rivet Machinery | Radial, Orbital, CNC | $$$ | Automotive, Aerospace |

| Shenzhen Yijin Hardware | Pneumatic, Hydraulic | $$ | Custom Solutions |

| PennEngineering | PEMSERTER® Series | $$$$ | Automotive, Electronics |

| Atlas Copco (Henrob) | Self-piercing Systems | $$$$ | Automotive |

| BalTec Machinery | Radial, Orbital | $$$ | Medical, Automotive |

| Wuxi Yuke | Blind Rivet Machines | $$ | General Industry |

| AGME | Orbital, Radial | $$$ | Industry 4.0 Integration |

| Bollhoff | RIVSET®, ONSERT® | $$$$ | Lightweight Construction |

| Zhang Nian Fa | Pneumatic, Hydraulic | $$ | Furniture, Automotive |

| San Xing Machinery | Hydraulic Systems | $$ | Production Lines |

Future Trends in riveting machine Manufacturing

The riveting machine industry in China is evolving rapidly, with several key trends shaping its future:

- Automation and Robotics: Increased integration of robotic systems for higher precision and efficiency.

- Smart Manufacturing: Implementation of IoT and AI technologies for predictive maintenance and quality control.

- Eco-friendly Solutions: Development of energy-efficient riveting machines and processes.

- Lightweight Materials: Adaptation of riveting technologies for new lightweight materials used in automotive and aerospace industries.

- Customization: Growing demand for flexible, multi-functional riveting machines capable of handling various materials and rivet types.

Choosing the Right riveting machine Manufacturer

When selecting a riveting machine manufacturer in China, consider the following factors:

- Technical Expertise: Evaluate the manufacturer’s experience and knowledge in your specific industry.

- Quality Control: Look for manufacturers with robust quality management systems and relevant certifications.

- After-sales Support: Ensure the manufacturer offers comprehensive technical support and spare parts availability.

- Customization Capabilities: Choose a manufacturer that can tailor solutions to your specific needs.

- Financial Stability: Research the company’s financial health to ensure long-term partnership potential.

- Export Experience: For international buyers, select manufacturers with a proven track record in exports and global customer service.

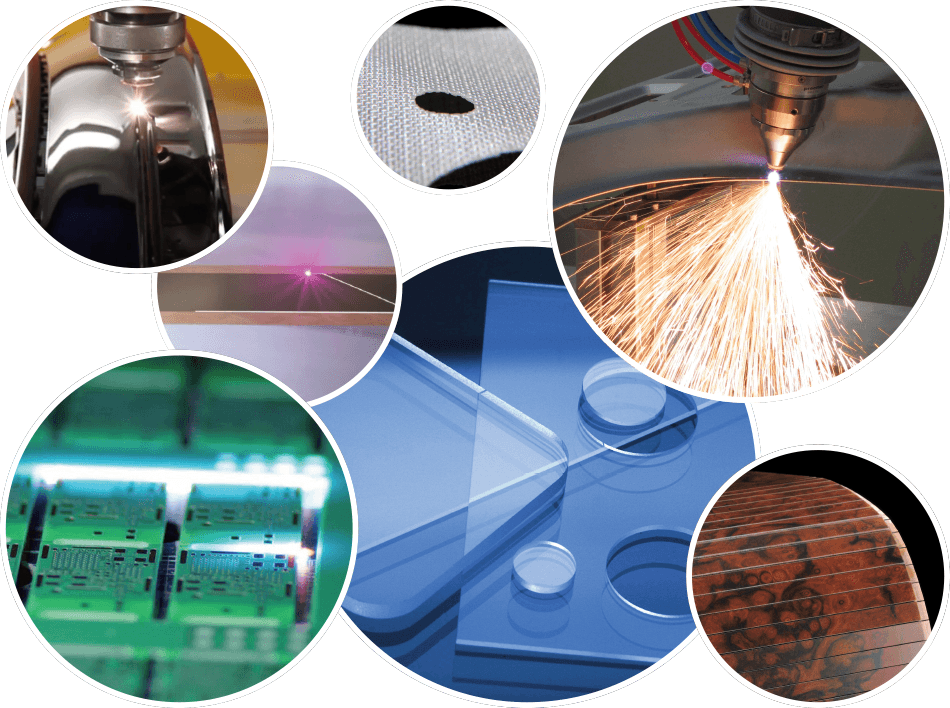

What is a Riveting Machine?

A riveting machine is a specialized tool that joins materials using rivets, automating the process of inserting and deforming rivets to create secure, permanent connections between two or more pieces of material. These machines are essential in industries such as automotive, aerospace, construction, and electronics manufacturing, offering efficient and reliable joining solutions for various materials and applications.

Key Components of Riveting Machines

Riveting machines typically consist of four main components:

- Feed Mechanism: Automatically supplies rivets to the riveting head

- Rivet Setting Tool: Deforms the rivet to secure the joint

- Power Source: Can be pneumatic, hydraulic, or electric

- Control System: Regulates pressure, timing, and rivet placement

Types of Riveting Machines

There are six primary types of riveting machines, each designed for specific applications:

| Type | Description |

|---|---|

| Orbital | Uses smooth, orbital motion for high-precision rivet formation |

| Radial | Employs “rose-petal” radial motion for durable joints with minimal force |

| Pneumatic | Powered by compressed air for fast and efficient riveting |

| Hydraulic | Uses hydraulic pressure for heavy-duty riveting tasks |

| Electric | Operates with electric motors for consistent and controlled installation |

| Manual | Hand-operated tools suitable for smaller-scale projects |

How Do Riveting Machines Work?

The basic process of a riveting machine involves four steps:

- Positioning materials to be joined

- Inserting a rivet into pre-drilled holes

- Applying force to deform the rivet’s tail

- Creating a secure joint that resists vibration

Advanced automated riveting machines often include features such as Programmable Logic Controllers (PLCs) for precise control, force and displacement monitoring for quality assurance, and adjustable settings to accommodate different materials and rivet sizes.

Conclusion

China’s riveting machine manufacturing industry is thriving, providing a diverse array of high-quality and innovative solutions for global markets. The top 10 manufacturers highlighted in this article exemplify the best China has to offer, featuring advanced technology, competitive pricing, and excellent customer service. By assessing your specific needs alongside each manufacturer’s strengths, you can identify the ideal partner to enhance your business growth and operational efficiency.