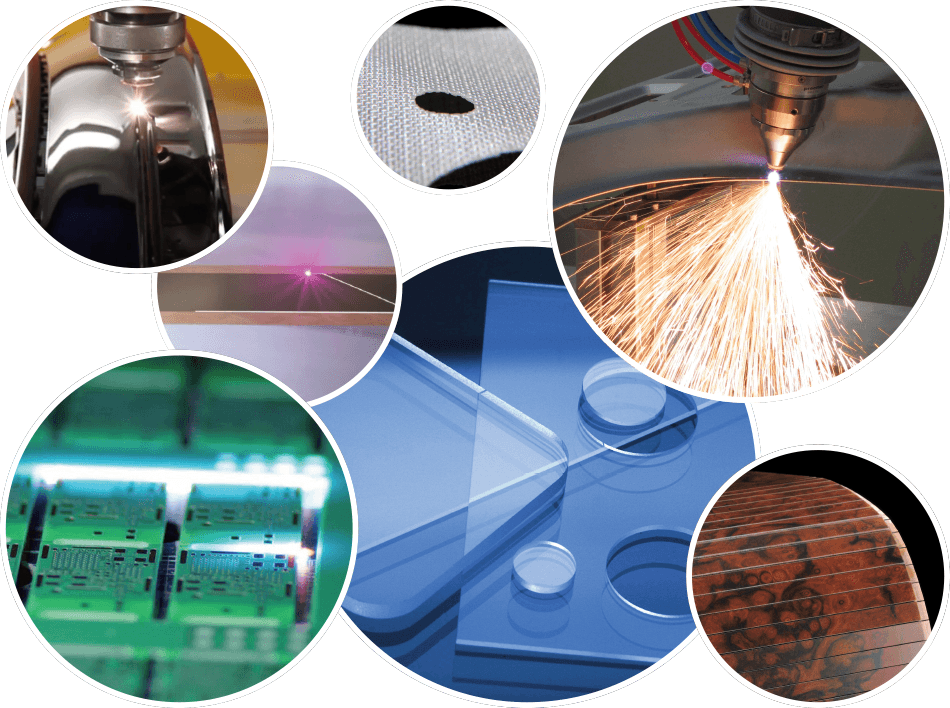

Vertical 5-axis laser machining has revolutionized precision manufacturing, offering unparalleled accuracy and efficiency in producing complex components. As we look ahead to 2025, selecting the right manufacturer is crucial for businesses aiming to stay competitive in industries ranging from aerospace to medical device production. This article examines the top 10 vertical 5-axis laser machining manufacturers, providing insights to help you make an informed decision.

Overview

The global 5-axis CNC machining center market is projected to reach $105.3 billion by 2025, growing at a CAGR of 6.5%. This growth is driven by increasing demand for high-precision components in aerospace, automotive, and medical sectors. Vertical 5-axis laser machining, in particular, is seeing rapid adoption due to its ability to create intricate geometries with sub-micrometer accuracy.

Top 10 Vertical 5-Axis Laser Machining Manufacturers

DMG MORI

DMG MORI stands as a global leader in the machine tool industry, specializing in high-precision vertical 5-axis machining centers and innovative laser machining solutions.

Business Type: Manufacturing of machine tools, including vertical 5-axis machining centers and laser machining systems

Headquarters: Tokyo, Japan (Global Headquarters) and Nara, Japan (Second Headquarters)

Main Markets: Global, with strong presence in Asia, Europe, and North America

Establishment Year: 1948

Certificates/Awards: Multiple awards for innovative products, including recognition for the MU-S600V 5-axis machining center

DMG MORI is a pioneer in vertical 5-axis machining, offering cutting-edge solutions tailored to diverse manufacturing needs. Their flagship NMV 5000 DCG exemplifies innovation with proprietary technologies like Direct Drive Motor (DDM) for zero backlash, Driven at the Center of Gravity (DCG) for vibration control, and Octagonal Ram Construction (ORC) for high-speed precision.

“With 113 global offices and production facilities like Tianjin capable of producing 1,000 units annually, DMG MORI ensures unmatched customer support and capacity.”

The company stays ahead of trends, addressing shifts toward electric vehicles and integrating AI into manufacturing. At its Nara Campus System Solution Plant, DMG MORI delivers turnkey solutions, combining advanced machine tools, automation systems, and software for seamless project execution.

With a global presence and continuous innovation in 5-axis machining and laser technology, DMG MORI is a trusted partner for manufacturers seeking efficient, high-quality solutions for complex components.

Mazak

Mazak stands as a global leader in the machine tool industry, renowned for its cutting-edge vertical 5-axis machining centers and innovative laser machining solutions. With a century-long history of innovation, Mazak has established itself as a pioneer in advanced manufacturing technologies.

Business Type: Manufacturing of machine tools, including vertical 5-axis machining centers, CNC lathes, and laser processing systems

Headquarters: Oguchi, Aichi Prefecture, Japan

Main Markets: Global, with strong presence in Asia, Europe, and North America

Establishment Year: 1919

Certificates/Awards: Multiple awards for innovative products, including recognition for the MU-S600V 5-axis machining center and the 2011 Boeing Performance Excellence Award

Mazak’s commitment to innovation shines through its state-of-the-art vertical 5-axis machining centers. The flagship VARIAXIS series, including the VARIAXIS j-500/5X, showcases:

- Simultaneous 5-axis machining expertise

- Proprietary roller gear cam technology

- Superior accuracy, rigidity, and durability

“Mazak’s global network of 10 manufacturing facilities and 80+ technology centers ensures unmatched production capacity and customer support.”

The Oguchi Plant, established in 1961, exemplifies Mazak’s advanced manufacturing processes:

- Model for high-precision assembly

- Strict environmental controls

- Processes 12.3 million data points daily

Mazak’s value proposition centers on complete turnkey solutions. The INTEGREX i-500 multi-tasking machine embodies this approach with its “DONE-IN-ONE” concept:

- Integrates turning, milling, 5-axis capabilities, gear machining, and laser technology

- Boosts production efficiency

- Processes raw materials to finished products in a single setup

This integrated approach, combined with global presence and continuous innovation, positions Mazak as a trusted partner for manufacturers across aerospace, automotive, and medical sectors.

Zimmermann Inc.

Zimmermann Inc. stands as a leading innovator in the machine tool industry, specializing in high-precision vertical 5-axis machining centers and advanced milling solutions. With a legacy dating back to 1933, the company has established itself as a trusted partner for manufacturers seeking cutting-edge machining technology.

Business Type: Manufacturing of machine tools, including vertical 5-axis machining centers and portal milling machines

Headquarters: Wixom, Michigan, USA

Main Markets: Global, with strong presence in North America, Europe, and Asia

Establishment Year: 2004 (North American subsidiary; parent company established in 1933)

Certificates/Awards: ISO 9001:2015 certified

Zimmermann Inc. specializes in modular machine systems with thermo-symmetrical gantry designs, offering:

- High accuracy and design flexibility

- Flagship FZU/FZP42 5-axis milling machine

- Centrally guided Z-slide for stability in heavy workpiece machining

“Zimmermann’s thermo-symmetrical design results in more dynamic, productive, and energy-efficient machines.”

Global Reach, Local Support:

- Worldwide manufacturing facilities and technical centers

- North American hub in Wixom, Michigan

- Ideal for aerospace, automotive, and alternative energy sectors

Value Proposition:

- Tailored, high-performance milling solutions

- German engineering expertise with local support

- Modular systems adaptable to diverse manufacturing needs

Zimmermann Inc. enables manufacturers to enhance vertical 5-axis machining capabilities, staying competitive in demanding markets through continuous innovation and industry-specific expertise.

Matsuura

Matsuura Machinery Corporation stands as a premier global manufacturer of CNC machine tools, specializing in high-precision vertical 5-axis machining centers. With a legacy dating back to 1935, Matsuura has established itself as an industry leader known for innovative excellence and cutting-edge engineering.

Business Type: Manufacturing of machine tools, including 5-axis vertical machining centers, horizontal machining centers, and metal laser sintering hybrid milling machines

Headquarters: Fukui-city, Fukui Prefecture, Japan

Main Markets: Global, with strong presence in Asia, Europe, and North America

Establishment Year: 1935

Certificates/Awards: ISO 9001:2015 certified, recipient of multiple awards for innovative products including recognition for the MX-520 5-axis machining center

Matsuura’s commitment to innovation shines through its state-of-the-art vertical 5-axis machining centers:

- MX series and MAM72 series

- Proprietary Intelligent Protection System

- Flagship models: MX-520 and MAM72-52V

“Matsuura’s expertise in simultaneous 5-axis machining offers unparalleled precision and efficiency for complex component manufacturing.”

Global Reach and Impact:

- Annual turnover: 17.78 billion yen (FY2023)

- Export ratio: 78%

- Industries served: aerospace, automotive, medical

- Notable achievement: NASA used Matsuura tools to reduce Space Shuttle Discovery’s fuel tanks by 4 tons

Value Proposition:

- Complete, high-performance machining solutions

- Modular systems (e.g., MX-520 PC4 with 4-pallet system)

- Flexibility for diverse manufacturing needs

Matsuura’s focus on continuous innovation and industry-specific expertise, coupled with their commitment to “Do what no one else can do,” positions them as a key enabler for manufacturers in vertical 5-axis machining across demanding global markets.

Aerotech

Aerotech stands as a global leader in precision motion control and automation solutions, with a strong focus on advanced manufacturing technologies including vertical 5-axis machining systems. The company’s innovative approach to motion control has positioned it at the forefront of high-precision manufacturing across various industries.

Business Type: Manufacturing of precision motion control systems, including 5-axis machining centers, nanopositioning stages, and laser processing systems

Headquarters: Pittsburgh, Pennsylvania, USA

Main Markets: Global, with strong presence in North America, Europe, and Asia

Establishment Year: 1970

Certificates/Awards: ISO 9001:2015 certified, recipient of multiple awards for innovative products including recognition for the AGV5D 5-axis laser precession scanner

Aerotech’s innovation shines through its state-of-the-art vertical 5-axis machining systems:

- Five-Axis Precision Motion System with coordinated control

- AGV5D 5-axis laser precession scanner

- ANT130V-5 nanopositioning stage

“Aerotech’s expertise in high-precision motion control offers unparalleled accuracy and efficiency for complex component manufacturing.”

Global Reach and Industry Impact:

- Worldwide engineering and manufacturing facilities

- Key industries: aerospace, medical devices, semiconductors

- Innovative technologies: noncontact direct-drive design in ANT130V-5 stage

Value Proposition:

- Complete, high-performance motion control solutions

- Modular systems for diverse manufacturing needs

- Focus on continuous innovation and industry-specific expertise

Aerotech’s commitment to “Innovation at every stage” positions them as a key enabler for manufacturers in vertical 5-axis machining across demanding global markets.

Okuma

Okuma Corporation stands as a global leader in the machine tool industry, renowned for its cutting-edge vertical 5-axis machining centers and innovative CNC solutions. With a legacy spanning over a century, Okuma has established itself as a pioneer in advanced manufacturing technologies.

Business Type: Manufacturing of CNC machine tools, including vertical 5-axis machining centers, lathes, grinders, and CNC controls

Headquarters: Oguchi-cho, Niwa-gun, Aichi Prefecture, Japan

Main Markets: Global, with strong presence in Asia, North America, and Europe

Establishment Year: 1898

Certificates/Awards: ISO 9001:2015 certified, recipient of multiple awards including the Nikkan Kogyo Shimbun Top 10 New Products Award for the MU-500VA 5-axis multitasking vertical machining center

Okuma’s innovation shines through its state-of-the-art vertical 5-axis machining centers:

- GENOS M460V-5AX and MU-4000V

- Proprietary Thermo-Friendly Concept

- Intelligent Technologies suite

“Okuma’s expertise in simultaneous 5-axis machining offers unparalleled precision and productivity for complex component manufacturing.”

Global Reach and Industry Impact:

- Headquarters: Aichi Prefecture

- Key plant: Kani, Gifu Prefecture

- Annual turnover: 17.78 billion yen (FY2023)

- Export ratio: 78%

- Key industries: aerospace, automotive, medical

- Notable achievement: NASA used Okuma tools for Space Shuttle Discovery

Value Proposition:

- “Single Source” philosophy: in-house design and manufacturing

- OSP-P500 CNC control system

- Focus on sustainable, energy-efficient production

Okuma’s century-long tradition of excellence and commitment to innovation position them as a key enabler for manufacturers in vertical 5-axis machining across demanding global markets.

HEDELIUS

HEDELIUS is a leading German manufacturer of high-performance vertical CNC machining centers, specializing in 3-axis, 4-axis, and 5-axis machines. With a focus on precision, efficiency, and reliability, HEDELIUS has established itself as a key player in the machine tool industry since its founding in 1967.

Business Type: Manufacturing of CNC machining centers, including vertical 5-axis machining centers and automation solutions

Headquarters: Meppen, Lower Saxony, Germany

Main Markets: Europe, with a strong presence in Germany and expanding global reach

Establishment Year: 1967

Certificates/Awards: ISO 9001:2015 certified, CrefoZert credit rating certificate

HEDELIUS’s innovation shines through its state-of-the-art vertical 5-axis machining centers:

- ACURA and TILTENTA series

- Proprietary Thermo-Friendly Concept

- Unique Z-axis designs for enhanced precision

“HEDELIUS’s expertise in simultaneous 5-axis machining offers unparalleled accuracy and productivity for complex component manufacturing.”

Production Capacity and Market Impact:

- 12,000 m² state-of-the-art facility in Meppen

- 250 employees

- Over 3,000 machining centers delivered across Europe

- Key industries: aerospace, automotive, tool and mold making, medical

Product Range:

- ACURA series: rotating/swivelling tables (A/C kinematics)

- TILTENTA series: swivelling main spindles with NC rotary tables (B/C kinematics)

Value Proposition:

- Flexible, high-performance machining solutions

- German engineering excellence

- Financial stability: 70% equity ratio

- Family-owned since 1967

HEDELIUS’s commitment to innovation and long-term customer success positions them as a key enabler for manufacturers in vertical 5-axis machining across demanding industries.

C.B. Ferrari

C.B. Ferrari, established in 1966, is a leading Italian manufacturer of high-precision 5 and 6-axis machining centers, automated systems, and turnkey milling and laser solutions. The company has positioned itself as a key player in the global machine tool industry, serving advanced high-tech manufacturing companies worldwide.

Business Type: Manufacturing of machine tools, including 5-axis machining centers, automated systems, and turnkey milling and laser solutions

Headquarters: Mornago (VA), Italy

Main Markets: Global, with a strong presence in aerospace, molds and equipment, medical, automotive, precision mechanics, and energy sectors

Establishment Year: 1966

Certificates/Awards: ISO 9001:2015 certified since April 29, 2015, accredited by DNV GL

C.B. Ferrari’s state-of-the-art vertical 5-axis machining centers, such as the A236, feature advanced technologies like SIEMENS SINUMERIK ONE numerical control with digital twin simulation. Designed for precision manufacturing, the A236 excels in producing turbine blades, impellers, blisks, and complex parts.

“With two facilities in Mornago and Modena, C.B. Ferrari has delivered over 4,500 machines worldwide.”

Key Strengths:

- MC Series: Slim nose electrospindles and automatic pallet changers

- Proprietary CAM software and Process Technology Simulation since 1984

- In-house production of Electro-Spindles and Turntables

As Italy’s third-largest machine tool exporter, C.B. Ferrari combines cutting-edge technology, reliability, and precision. Their focus on Industry 4.0 and Smart Manufacturing ensures they remain a trusted partner for advanced vertical 5-axis machining solutions.

Penta Machine Company

Penta Machine Company, formerly known as Pocket NC, is a pioneering manufacturer of compact, high-precision 5-axis CNC milling machines. The company has established itself as a leader in making advanced machining technology accessible to a wide range of users, from educational institutions to small-scale manufacturers and innovators.

Business Type: Manufacturing of compact 5-axis CNC milling machines and related software

Headquarters: Belgrade, Montana, USA

Main Markets: Global, with a strong presence in education, research, prototyping, and small-scale manufacturing sectors

Establishment Year: 2011

Certificates/Awards: Broke Montana’s Kickstarter funding record in 2016, raising $355,833 from 280 backers

Penta’s innovation shines through its compact 5-axis CNC milling machines:

- Flagship Pocket NC and newer Solo model

- Advanced features: servo-driven axes and ball screws

- Solo: industrial-grade capabilities in a door-sized package

“Penta Machine Company has delivered thousands of machines worldwide from its Belgrade, Montana facility.”

Product Range:

- Pocket NC V2-8Lite: affordable 5-axis CNC machining

- Solo: 14-slot automatic tool changer, flood coolant, in-process part probing

- Proprietary Kinetic Control software with Tool Center Point Control (TCPC)

Penta offers high-performance, accessible 5-axis machining solution for:

- Educators

- Researchers

- Small-scale manufacturers

Motto: “See the need, create the solution”

Penta’s commitment to “advancing the spirit of innovation” empowers users to bring ideas to life through advanced manufacturing technology.

Baison

Baison is a leading engineering company specializing in precision metal products and advanced manufacturing solutions, including vertical 5-axis machining. With a strong focus on innovation and quality, Baison has established itself as a key player in the global manufacturing industry.

Business Type: Manufacturing of precision metal products, CNC machining, laser cutting, and engineering services

Main Markets: Global, with a strong presence in industrial manufacturing sectors

Baison’s state-of-the-art manufacturing capabilities include:

- Advanced CNC machining centers

- Laser cutting technologies

- Expertise in vertical 5-axis machining

“Baison’s product range caters to diverse industries such as aerospace, automotive, and electronics.”

Comprehensive Solutions:

- CNC programming

- 3D modeling

- Computer-aided design

- End-to-end client solutions

Production Highlights:

- Cutting-edge vertical and horizontal machining centers

- Capacity for workpieces up to 3500 mm in diameter

Baison offers high-quality, custom-engineered solutions combining:

- Cutting-edge technology

- Exceptional precision and reliability

- Continuous innovation

- Strict quality standards

Baison stands out as a versatile and capable provider in precision manufacturing and vertical 5-axis machining.

OPMT Laser

OPMT Laser, a division of Guangdong Original Point Intelligent Technology Co., Ltd., is a leading innovator in the field of advanced CNC systems and laser machine tools. The company has established itself as a key player in the development and manufacturing of cutting-edge laser processing solutions.

Business Type: Manufacturing of CNC systems, laser machine tools, and precision processing solutions

Headquarters: Foshan, Guangdong, China

Main Markets: Global, with a focus on industrial manufacturing sectors

Establishment Year: 2015

OPMT Laser’s state-of-the-art product offerings include the Micro3DL530V, a five-axis femtosecond laser machining center ideal for carbide insert manufacturing and high-precision processes like cutting tool grinding and mold 3D texturing.

“The 563V Vertical 5-Axis Machining Center excels in processing mold steel and high-temperature alloys, featuring a fan-shaped 30-tool magazine and beam-type structure.”

Value Proposition:

- High-performance laser processing and CNC machining solutions

- Emphasis on efficiency, automation, and precision

- Advanced technologies to meet evolving global manufacturing needs

OPMT Laser’s focus on innovation and comprehensive solutions positions it as a trusted partner for manufacturers seeking cutting-edge precision machining capabilities.

| Manufacturer | Key Features | Technologies | Market Strengths |

|---|---|---|---|

| DMG MORI | High precision machining centers, large capacity | Direct Drive Motor, Driven at Center of Gravity | Global leader, diverse industry applications |

| Mazak | Multi-tasking capabilities, DONE-IN-ONE concept | VARIAXIS series, INTEGREX i-500 | Strong presence in aerospace, automotive, medical |

| Zimmermann Inc. | Modular machine systems, thermo-symmetrical gantry | Centrally guided Z-slide | Expertise in large, complex parts machining |

| Matsuura | Simultaneous 5-axis machining, high reliability | Intelligent Protection System | Trusted in aerospace, automotive, medical sectors |

| Aerotech | High-precision motion control, laser processing | AGV5D 5-axis laser scanner | Leader in medical technology, microelectronics |

| Okuma | Thermal stability, intelligent technologies | Thermo-Friendly Concept, OSP-P500 CNC | Comprehensive solutions for various industries |

| HEDELIUS | Flexible machining solutions, German engineering | ACURA and TILTENTA series | Strong in European markets, precision manufacturing |

| C.B. Ferrari | High-performance machining for complex parts | SIEMENS SINUMERIK ONE | Expertise in turbine blades, impellers, aerospace |

| Penta Machine Company | Compact, affordable 5-axis CNC machines | Kinetic Control software, TCPC | Education, research, small-scale manufacturing |

| Baison | Precision metal products, comprehensive solutions | Advanced CNC and laser technologies | Versatile provider across industrial sectors |

| OPMT Laser | Femtosecond laser machining, CNC systems | Micro3DL530V, 563V Vertical 5-Axis Center | Cutting-edge solutions for precision processing |

What is Vertical 5-Axis Laser Machining?

Vertical 5-Axis Laser Machining is an advanced manufacturing technology that combines 5-axis machining precision with laser cutting versatility. This innovative process enables complex, three-dimensional cutting and shaping of materials with high accuracy and efficiency.

Key Features of Vertical 5-Axis Laser Machining

- Five Axes of Motion:

- Three linear axes: X, Y, and Z

- Two rotary axes: Typically A and B, or B and C

- Vertical Configuration: Main spindle oriented vertically, ideal for specific workpieces and operations

- Laser Cutting Technology: Uses high-powered laser beam for cutting, engraving, and shaping materials

Applications and Advantages

| Application | Advantage |

|---|---|

| Complex 3D Parts | Ideal for intricate geometries in automotive, aerospace, and medical industries |

| PCD and CBN Tool Processing | Effective for machining ultra-hard materials |

| Flexible Manufacturing | Handles wide range of materials and part sizes |

| High Precision | Offers accuracy and fine surface finishes, reducing secondary operations |

| Improved Efficiency | Combines multiple operations in a single setup, boosting productivity |

Machine Characteristics

- High-Speed Spindles: Often exceed 30,000 RPM for efficient material removal

- Advanced Motion Control: Uses sophisticated software for precise axis coordination

- Automation Compatibility: Integrates with automated material handling systems

- Thermal Management: Incorporates cooling systems for extended operation accuracy

What industries benefit most from this technology?

Automotive, aerospace, and medical industries benefit significantly due to the ability to create complex 3D parts with high precision.

How does it improve manufacturing efficiency?

It combines multiple operations in a single setup, reducing production time and increasing overall productivity.

What materials can be processed?

It can handle a wide range of materials, including ultra-hard substances like polycrystalline diamond (PCD) and cubic boron nitride (CBN).

Vertical 5-Axis Laser Machining represents a cutting-edge solution for manufacturers seeking to produce complex parts with high precision and efficiency. Its combination of multi-axis movement and laser technology opens up new possibilities in advanced manufacturing processes.

Conclusion

The vertical 5-axis laser machining industry continues to evolve rapidly, with manufacturers pushing the boundaries of precision and efficiency. When selecting a manufacturer, consider factors such as specific industry needs, budget constraints, and required features. The top 10 manufacturers listed here represent the forefront of innovation in this field, each offering unique strengths to meet diverse manufacturing challenges.

For further exploration, consider researching:

- Advancements in laser technology for machining

- Industry-specific applications of 5-axis machining

- Integration of AI and machine learning in CNC operations

By staying informed about the latest developments and choosing the right manufacturer, businesses can leverage vertical 5-axis laser machining to gain a competitive edge in the rapidly evolving manufacturing landscape of 2025 and beyond.