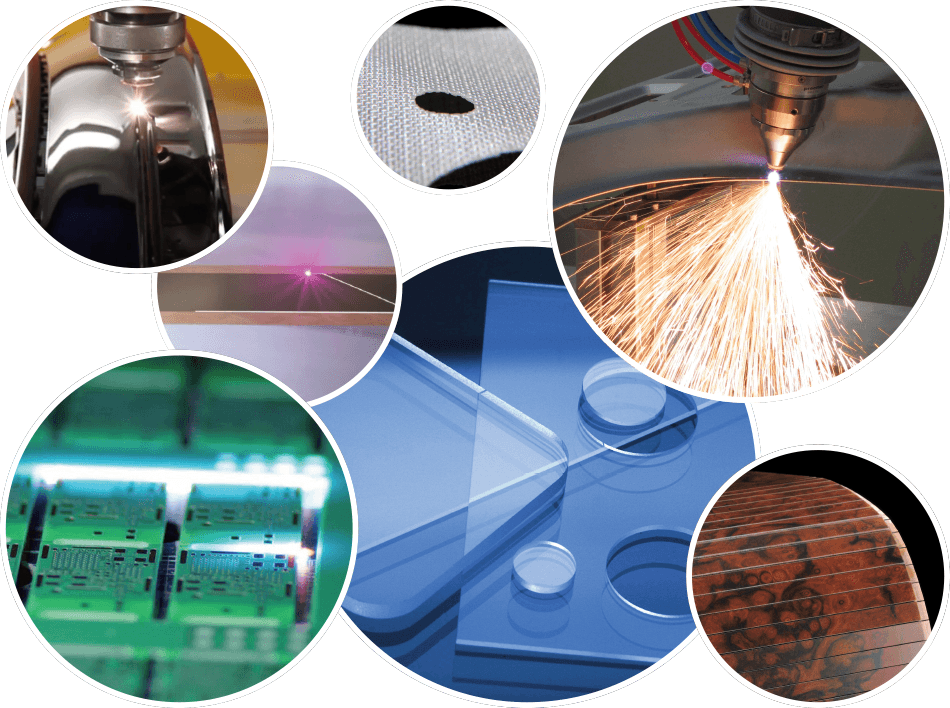

Small laser welding machines have gained significant popularity due to their ability to revolutionize precision and efficiency in various manufacturing applications. These advanced welding technologies are increasingly being adopted across industries, making the selection of the right manufacturer essential for achieving optimal results. In this article, we will highlight the top suppliers of small laser welding machines, providing valuable insights into their product offerings and market positions.

Overview

The small laser welding machine industry is currently experiencing significant growth, driven by advancements in technology and increasing demand across various sectors. As of 2025, the laser welding machine market is projected to expand at a compound annual growth rate (CAGR) of 4.73%, reaching an estimated value of approximately $373.97 million. This growth is attributed to the numerous advantages of laser welding over traditional methods, which include enhanced precision, reduced operational costs, and the capacity for automation in manufacturing processes.

Top 10 Small Laser Welding Machine Suppliers

TRUMPF

TRUMPF is a globally recognized leader in the field of laser technology and industrial manufacturing solutions, specializing in innovative machine tools and laser systems. With a strong presence in the North American market, TRUMPF has established itself as a key player among small laser welding machine suppliers, offering advanced solutions that cater to various industries.

Website: www.trumpf.com

Business Type: Manufacturer of laser welding machines and industrial lasers

Headquarters: Farmington, Connecticut, USA

Main Product: TruLaser Weld 1000

Main Markets: North America, Europe, Asia

Establishment Year: 1969

Certificates/Awards: Microsoft Intelligent Manufacturing Award, various ISO certifications

TRUMPF exemplifies innovation in laser technology, particularly in the realm of laser welding systems that prioritize efficiency and precision. The TruLaser Weld 1000 is specifically designed for small businesses entering the automated welding sector, enhancing productivity while enabling minimal distortion in thin sheet welding through its advanced three-kilowatt solid-state laser. This entry-level machine features a dual work area, allowing simultaneous loading and welding, which significantly reduces downtime and boosts output.

In addition to the TruLaser Weld 1000, TRUMPF offers the TruLaser Station 7000, a compact 3D laser welding solution ideal for small assemblies like sensors and medical devices. This system is known for its flexibility and ability to produce high-quality weld seams without post-processing, making it essential in precision-demanding industries. With state-of-the-art manufacturing capabilities in North America, TRUMPF ensures high production capacity while adhering to stringent quality standards.

What sets TRUMPF apart is its robust technological advancements and customer-focused business models. The company has adopted a Pay per Part model, allowing clients to utilize machines on a per-use basis while TRUMPF manages operations remotely. This approach not only addresses labor shortages but also enhances overall productivity and efficiency. TRUMPF’s commitment to quality, competitive pricing, and cutting-edge technology solidifies its reputation as a leading supplier of laser welding machines in the industry.

Han’s Laser

Han’s Laser Technology Industry Group Co., Ltd. is a leading global provider of industrial laser solutions, renowned for its innovative technology and comprehensive product offerings in the laser equipment sector. Established in 1996, the company has positioned itself as a flagship in the Chinese national laser industry and is recognized worldwide for its advanced laser welding machines.

Website: www.hanslaserus.com

Business Type: Manufacturer and supplier of industrial laser equipment, specializing in laser welding machines.

Headquarters: San Jose, California, USA

Main Product: Hand-held and stationary laser welding machines, including the DZW-PRO series.

Main Markets: North America, Europe, Asia-Pacific

Establishment Year: 1996

Certificates/Awards: ISO 9001 (Quality Management), ISO 14001 (Environmental Management), CE Certification, Guangdong Provincial Science and Technology Progress Award.

Han’s Laser stands out in the industrial laser solutions market, recognized for its cutting-edge technology and extensive product line. With over 300 patents and a commitment to quality, the company operates multiple manufacturing facilities across China, encompassing approximately 495,024 square meters of intelligent manufacturing space. This robust infrastructure supports a significant production capacity, allowing Han’s Laser to efficiently meet diverse customer needs. In 2022, the company achieved annual sales of $2.17 billion, underscoring its strong market presence.

The product portfolio includes over 200 models of industrial laser machines tailored for applications in electronics, automotive components, medical devices, and jewelry. Their hand-held laser welding machines are particularly notable for their efficiency and minimal heat-affected zones, making them ideal for precision tasks while lowering operational costs. Han’s Laser integrates advanced technologies such as fiber lasers and CO2 lasers, ensuring superior performance and reliability across its offerings.

Han’s Laser’s value proposition lies in its dedication to innovation and customer satisfaction. By combining state-of-the-art technology with competitive pricing and exceptional support services, Han’s Laser has established itself as a trusted partner for businesses seeking high-quality laser welding solutions tailored to their specific requirements. This commitment to excellence positions Han’s Laser as a leader among small laser welding machine suppliers globally.

Baison Laser

Baison Laser is a prominent player in the laser technology industry, specializing in innovative solutions for laser welding, cutting, and marking. Established in the early 2000s, Baison has quickly gained recognition for its high-quality products and exceptional customer service, positioning itself as a trusted supplier among small laser welding machine manufacturers.

Website: baisonlaser.com

Business Type: Manufacturer of laser welding machines and systems

Headquarters: Shenzhen, Guangdong, China

Main Product: Hand-held laser welding machines and industrial welding robots

Main Markets: Global markets including North America, Europe, and Asia

Establishment Year: 2004

Certificates/Awards: ISO 9001 Certification, CE Certification, over 300 patents in laser technology

Baison Laser specializes in customized laser welding solutions that cater to diverse industrial needs. With a modern manufacturing facility covering over 50,000 square meters and a dedicated team of more than 500 professionals, the company ensures efficient production and timely delivery of high-quality laser welding machines. Baison’s commitment to research and development has led to significant advancements in fiber and CO2 laser technologies, which enhance precision and operational efficiency.

The product lineup includes handheld laser welders capable of working with various materials, such as steel, aluminum alloys, and titanium. These machines are engineered for high precision in demanding applications, making them ideal for industries like automotive manufacturing and electronics. Baison Laser also prioritizes after-sales support, providing comprehensive training and maintenance services to help clients maximize their investments.

Baison Laser’s competitive edge lies in its unwavering dedication to quality at attractive prices. By leveraging cutting-edge technology and a customer-focused approach, the company consistently meets and exceeds market expectations. This focus on innovation and customer satisfaction has established Baison as a leader among small laser welding machine suppliers, making it the preferred partner for businesses seeking reliable and efficient laser solutions.

Amada Weld Tech

Amada Weld Tech is a recognized leader in the laser welding industry, specializing in advanced welding technologies and solutions. With a strong commitment to innovation and quality, the company has established itself as a trusted partner for manufacturers seeking precision and reliability in their welding processes.

Website: www.amadaweldtech.eu

Business Type: Manufacturer and Supplier of Laser Welding Equipment

Headquarters: Munich, Germany

Main Product: Laser Welding Machines

Main Markets: Automotive, Electronics, Medical, Aerospace, IT & Multimedia

Establishment Year: 1972

Certificates/Awards: ISO 9001 Certification, CE Marking, Various Industry Awards for Innovation

Amada Weld Tech operates cutting-edge production facilities in Munich, Germany, Eindhoven, Netherlands, and Cambridge, UK. These state-of-the-art locations enable the company to manufacture a diverse array of laser welding machines, specifically designed to meet the unique demands of various industries, including automotive and electronics. With impressive annual output capabilities, Amada Weld Tech delivers high-quality solutions that cater to both intricate electronic components and robust automotive parts.

The company’s extensive product lineup features not only advanced laser welders but also laser markers and resistance welding systems. Noteworthy innovations include the Real-time Power Feedback (RPF) technology, which optimizes laser power delivery for superior welding quality. Additionally, the integration of IoT technologies allows for real-time monitoring and control of production processes, enhancing efficiency and reliability across operations.

Amada Weld Tech’s commitment to quality and customer satisfaction sets it apart in the competitive landscape of laser welding solutions. By offering customized solutions that seamlessly integrate into existing manufacturing workflows, the company helps clients boost productivity while minimizing operational costs. With a focus on sustainable practices and ongoing innovation, Amada Weld Tech continues to lead the laser welding sector, providing exceptional value to customers globally.

Coherent

Coherent, Inc. is a prominent global player in the laser technology industry, renowned for its innovative solutions and extensive expertise in laser systems. With a legacy of over five decades, Coherent has established itself as a leader in providing advanced laser welding machines tailored for various industrial applications, particularly within the medical and automotive sectors.

Website: www.coherent.com

Business Type: Manufacturer of laser systems and components

Headquarters: Saxonburg, Pennsylvania, USA

Main Product: ExactWeld series of laser welding machines

Main Markets: North America, Europe, Asia

Establishment Year: 1966

Certificates/Awards: ISO 13485 certification for medical device manufacturing, various industry innovation awards

Coherent excels in producing high-precision laser welding machines, specifically the ExactWeld series, designed for a variety of industries, including medical devices and automotive electronics. These advanced systems feature automated welding capabilities that ensure superior quality and efficiency, making them ideal for small metal components. With state-of-the-art production facilities, Coherent maintains rigorous quality standards while achieving high-volume output. The company operates 22 application labs across 11 countries, emphasizing innovation through extensive research and development.

A cornerstone of Coherent’s success is its unwavering commitment to quality and reliability. The ExactWeld machines integrate SmartWeld technology, which enhances weld quality by accommodating wider gaps and improving fit-up tolerances. Furthermore, these systems are engineered for seamless integration into existing production lines, minimizing downtime and maximizing operational efficiency. Coherent also prioritizes customer support with a comprehensive service network, ensuring prompt assistance and maintenance.

Coherent’s unique value proposition lies in delivering high-performance laser solutions that enhance manufacturing precision and efficiency. The company’s dedication to innovation, combined with its robust manufacturing capabilities and focus on customer satisfaction, positions it as a trusted partner for businesses seeking advanced laser welding technologies. Whether addressing intricate welding challenges or providing customized solutions, Coherent remains at the forefront of the laser technology industry.

Jenoptik

Jenoptik is a leading global provider of photonic solutions, specializing in advanced laser technologies, including small laser welding machines. With a strong commitment to innovation and quality, Jenoptik has established itself as a trusted partner for various industries, including automotive, medical technology, and electronics.

Website: www.jenoptik.com

Business Type: Manufacturer and supplier of laser systems and photonic solutions

Headquarters: Jena, Thuringia, Germany

Main Product: Jenoptik Votan laser welding systems

Main Markets: North America, Europe, Asia-Pacific

Establishment Year: 1990

Certificates/Awards: ISO 9001 certification; Innovation Award at Blechexpo 2023 for the PSS-40/LCLW inspection station

Jenoptik excels in laser technology, offering high-precision solutions tailored for various industries, including automotive and electronics. With advanced production facilities and a skilled workforce of around 4,600 employees, the company ensures efficient manufacturing of diverse products such as laser cutting and welding systems.

The innovative use of adaptive control algorithms allows Jenoptik to optimize laser parameters in real-time, enhancing welding precision while significantly reducing operational costs through minimized material waste. Their commitment to quality is evident in their rigorous testing and inspection processes, ensuring that every product adheres to strict performance standards.

By providing cutting-edge laser welding solutions, Jenoptik positions itself as a preferred supplier for businesses seeking reliable and efficient systems. Their focus on innovation and quality not only meets industry demands but also drives sustainable growth for their clients.

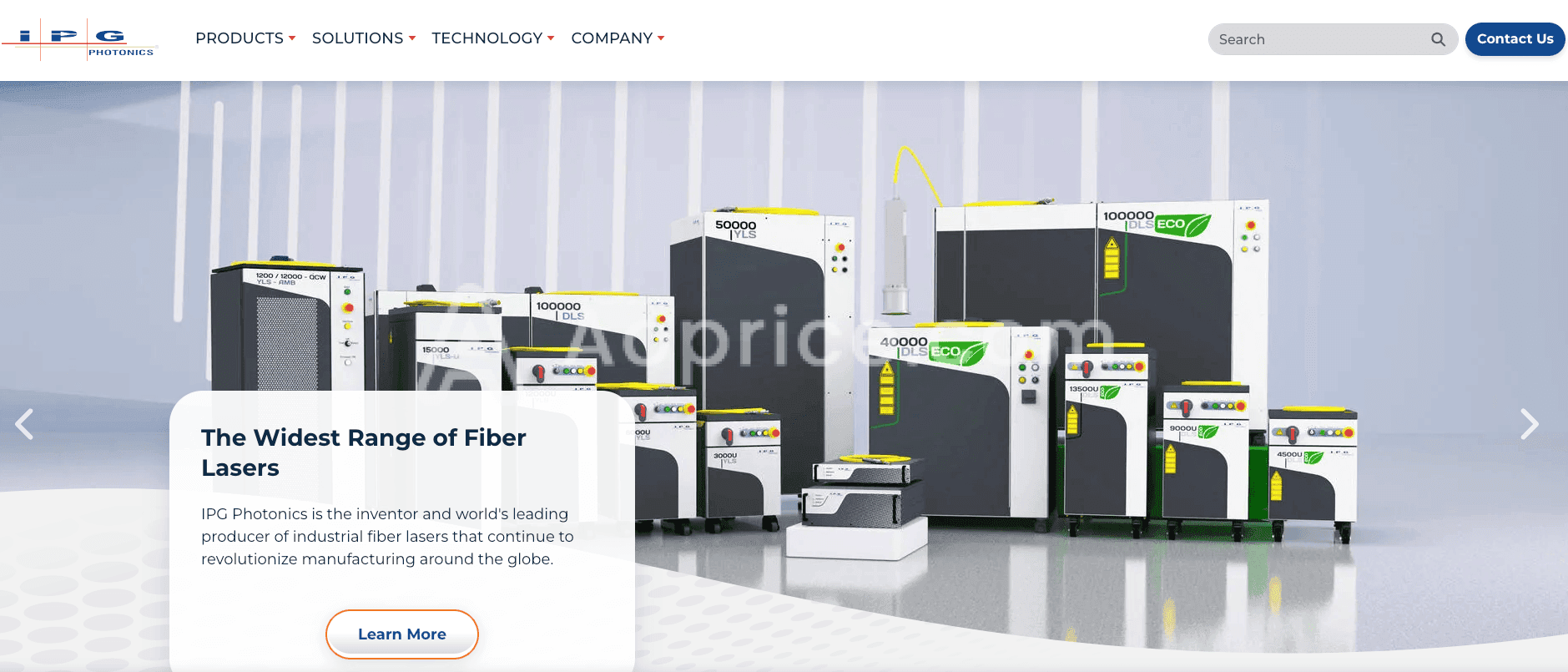

IPG Photonics

IPG Photonics Corporation is a global leader in high-power fiber laser technology, specializing in the development and manufacture of advanced laser solutions for various industrial applications, including small laser welding machines. The company’s innovative products cater to a diverse range of sectors, positioning IPG as a key player in the laser manufacturing industry.

Website: www.ipgphotonics.com

Business Type: Manufacturer and supplier of fiber lasers and amplifiers

Headquarters: Marlborough, Massachusetts, USA

Main Product: LightWELD series (handheld laser welding systems)

Main Markets: North America, Europe, Asia

Establishment Year: 1990

Certificates/Awards: ISO 9001:2015 Certification, ISO 14001:2015 Certification, Laser Industry Innovator Award 2024

IPG Photonics is a leading innovator in fiber laser technology, renowned for its LightWELD series of portable laser welding systems. These compact devices are designed for high efficiency and ease of use, making them ideal for a range of applications in various industries. With manufacturing facilities strategically located in the United States, Germany, Russia, and Italy, IPG is well-positioned to meet the global demand for advanced laser welding solutions.

The LightWELD systems offer numerous advantages over traditional welding techniques such as MIG and TIG. They provide faster processing speeds, reduced labor costs, and minimal post-weld cleanup while maintaining high-quality welds across diverse materials. Advanced features like programmable settings and integrated safety mechanisms enhance user experience and operational efficiency. Furthermore, IPG’s commitment to sustainability is evident in its energy-efficient designs that lower operational costs and environmental impact.

Overall, IPG Photonics stands out in the laser welding equipment market by delivering exceptional value through innovative solutions that boost productivity and reduce total ownership costs. The company’s focus on quality, reliability, and customer satisfaction reinforces its position as a top supplier of handheld laser welders tailored to meet the evolving needs of manufacturers worldwide.

LaserStar Technologies

LaserStar Technologies is a leading manufacturer in the laser welding industry, recognized for its commitment to quality and innovation since its founding in 1957. The company specializes in high-precision laser systems that cater to a diverse range of applications, including welding, marking, and cutting. With a strong reputation for reliability and performance, LaserStar has established itself as a trusted partner for businesses seeking advanced laser solutions.

Website: laserstar.net

Business Type: Manufacturer of laser welding machines and systems

Headquarters: Orlando, Florida, United States

Main Product: Nd:YAG and Fiber Laser Welding Systems

Main Markets: United States, Europe, Asia

Establishment Year: 1957

Certificates/Awards: ISO Certification, Various Industry Awards for Innovation

LaserStar Technologies is a premier manufacturer specializing in micro-welding solutions, including small laser welding machines and systems for diverse applications such as marking and engraving. With advanced manufacturing facilities located in Florida, Rhode Island, and California, the company produces over 400 laser welding units annually, ensuring it meets the rising demand across industries like jewelry, medical devices, automotive, and electronics.

The company’s strengths lie in its unwavering commitment to innovation and customer satisfaction. LaserStar employs a skilled engineering team dedicated to enhancing product performance while offering competitive pricing. Its focus on lean manufacturing practices optimizes production efficiency and quality control. Notable advancements include Pulse Shaping Technology, which enables precise energy delivery during welding, safeguarding delicate materials from damage.

LaserStar Technologies distinguishes itself in the laser welding market through extensive industry experience, a dedication to quality, and innovative product offerings. By providing tailored solutions that align with customer needs, the company reinforces its status as a leading supplier of laser systems. With a focus on operational efficiency and cost reduction for clients, LaserStar is committed to driving advancements in laser technology while delivering exceptional value.

UltraFlex Power Technologies

UltraFlex Power Technologies stands as a leader in the industrial induction heating sector, specializing in innovative solutions that cater to a diverse range of applications, including laser welding technologies. With over 25 years of experience, the company has established a strong reputation for quality and reliability in the manufacturing of induction heating equipment.

Website: ultraflexpower.com

Business Type: Manufacturer of induction heating systems and laser welding machines

Headquarters: Ronkonkoma, New York, USA

Main Product: Compact and portable laser welding machines

Main Markets: North America, Europe, South America, and Asia

Establishment Year: 1994

Certificates/Awards: ISO 9001 certified; CE marked; UL and CSA certifications available upon request

UltraFlex Power Technologies is a leader in the laser welding industry, known for its innovative and efficient welding solutions. The company specializes in compact laser welding machines, designed to meet the diverse needs of manufacturers across various sectors. With production facilities located in both the USA and Europe, UltraFlex ensures high-quality standards while accommodating significant market demand.

The company’s SmartPower™ modular systems provide exceptional load-matching capabilities, enhancing performance across different applications. UltraFlex’s commitment to research and development drives continuous improvements in efficiency and effectiveness, positioning it as a preferred choice for businesses seeking reliable laser welding equipment.

In addition to advanced products, UltraFlex prioritizes customer support and service excellence. Comprehensive training programs and technical assistance empower clients to maximize their equipment’s potential. This focus on customer satisfaction, coupled with competitive pricing, solidifies UltraFlex’s reputation as a trusted supplier in the laser welding market. Overall, UltraFlex Power Technologies delivers outstanding value through its commitment to quality, innovative technology, and tailored solutions that enhance productivity for its clients.

Miller Electric

Miller Electric is a leading manufacturer in the welding industry, renowned for its innovative solutions and commitment to quality. Established in 1929, the company has built a strong reputation for producing high-performance welding machines and equipment, including advanced laser welding technologies. With a focus on safety, durability, and versatility, Miller Electric continues to set the standard for excellence in welding.

Website: millerwelds.com

Business Type: Manufacturing and distribution of welding machines and related equipment

Headquarters: Appleton, Wisconsin, USA

Main Product: OptX™ Handheld Laser Welder

Main Markets: North America, Europe, Asia-Pacific

Establishment Year: 1929

Certificates/Awards: ISO 9001 Certification, multiple industry awards for innovation and safety

Miller Electric excels in the welding equipment industry, offering a comprehensive range of small laser welding machines and advanced welding solutions tailored to diverse industrial applications. With state-of-the-art manufacturing facilities equipped with cutting-edge robotics and automation, Miller Electric delivers high-quality products that meet the demands of sectors ranging from automotive to aerospace. The company’s impressive annual production capacity positions it as a reliable partner for both small businesses and large enterprises seeking innovative welding technologies.

The OptX™ Handheld Laser Welder exemplifies Miller Electric’s commitment to innovation, utilizing laser technology for precise welding on lightweight materials. This machine enhances productivity while simplifying operations for users of all skill levels. Additionally, the ZoneFlow™ Fume Extraction Technology underscores the company’s focus on safety and efficiency by effectively capturing harmful fumes during the welding process.

Miller Electric’s unique value proposition lies in its ability to merge quality with competitive pricing, continuously advancing its technology to align with market trends. By prioritizing customer feedback and investing in research and development, Miller Electric remains at the forefront of the welding industry, providing dependable solutions that enhance productivity and safety for welders globally. With a strong emphasis on quality assurance and customer satisfaction, Miller Electric is dedicated to delivering exceptional value in every product it offers.

Comparison of Small Laser Welding Machine Suppliers

| Supplier | Key Features | Price Range (USD) | Specialties |

|---|---|---|---|

| TRUMPF | Fiber lasers, pulsed lasers | 10,000-50,000 | Sheet metal processing |

| Han’s Laser | Sensor systems, five-axis linkage | 15,000-60,000 | Diverse industrial applications |

| Baison Laser | High precision, energy-saving | 12,000-55,000 | Automated solutions |

| Amada Weld Tech | Advanced technology | 20,000-70,000 | Medical & aerospace industries |

| Coherent | High-performance industrial lasers | 25,000-80,000 | Versatile applications |

| Jenoptik | Customized solutions | 18,000-65,000 | Medical & automotive sectors |

| IPG Photonics | Compact hand-held machines | 22,000-75,000 | High efficiency |

| LaserStar Technologies | Manual & semi-automatic systems | 10,000-50,000 | Technical assistance |

| UltraFlex Power Technologies | Portable systems | 15,000-60,000 | Innovative applications |

| Miller Electric | Hand-held systems | 20,000-70,000 | Productivity enhancement |

Conclusion

In conclusion, selecting the right supplier for small laser welding machines is essential for manufacturers seeking efficiency and precision. The companies listed above represent some of the best options available in 2025. Each supplier brings unique strengths to the table that can cater to various industrial needs. As a leading manufacturer ourselves, we are committed to providing high-quality solutions that meet our customers’ evolving demands while maintaining excellence in service and innovation.