CNC milling machines play a crucial role in the global manufacturing landscape, enabling precision and efficiency across various industries. As the demand for high-quality machining solutions continues to rise, selecting the right manufacturer becomes essential for businesses aiming to enhance their production capabilities. This article explores the top ten CNC milling machine manufacturers of 2025, providing insights into their histories, product offerings, and market positions.

Overview of the CNC Milling Machine Industry

The CNC milling machine industry has witnessed significant growth in recent years, driven by advancements in technology and increasing demand for automation in manufacturing processes. According to industry reports, the global CNC machine market is projected to reach approximately $100 billion by 2025, with a compound annual growth rate (CAGR) of around 6% from 2020 to 2025. This growth is fueled by the rising need for precision engineering in sectors such as aerospace, automotive, and healthcare.

Key Market Trends:

- Technological Advancements: Integration of AI and IoT in CNC machines for enhanced operational efficiency.

- Customization Demand: Increasing requirement for tailored solutions to meet specific manufacturing needs.

- Sustainability Focus: Growing emphasis on eco-friendly manufacturing practices and energy-efficient machines.

Top 10 CNC Milling Machine Manufacturers

DMG MORI

DMG MORI is a leading global manufacturer in the CNC milling machine industry, renowned for its innovative technologies and high-precision machining solutions. With a strong commitment to quality and customer satisfaction, the company has established itself as a key player in the machine tool sector, offering a diverse range of products and services that cater to various industrial applications.

Business Type: Manufacturer of CNC machine tools and automation solutions

Headquarters: Tokyo, Japan; Nara City, Nara Prefecture, Japan

Main Markets: Global presence with significant markets in Europe, North America, and Asia

Establishment Year: 1948

Certificates/Awards: ISO 9001 certification, various industry awards for innovation and excellence in manufacturing

DMG MORI excels in providing advanced CNC milling machines that define performance and reliability. With annual production of 8,000 to 10,000 machines, the company operates multiple facilities across Japan, Germany, Italy, Poland, and the USA. Their extensive product range includes:

- Vertical and horizontal machining centers

- 5-axis machines

- Specialized solutions for complex tasks

The integration of cutting-edge technologies like ULTRASONIC and LASERTEC enhances capabilities, enabling the processing of advanced materials such as composites and titanium.

“One of DMG MORI’s key strengths is its commitment to digital transformation and automation.”

The company has developed an integrated production platform that optimizes manufacturing processes through machine tools and software solutions. Their focus on sustainability is evident in the creation of energy-efficient machines designed to minimize environmental impact while maximizing productivity. With a robust global sales and service network of over 113 locations in 43 countries, DMG MORI provides exceptional support throughout the lifecycle of its machines.

DMG MORI stands out in the CNC milling machine market due to its innovative technology, comprehensive product offerings, and dedication to customer service. The company’s unique value proposition lies in delivering tailored solutions that enhance operational efficiency while maintaining high standards of quality and precision.

Mazak

Mazak Corporation, a prominent player in the CNC milling machine industry, is recognized for its innovative manufacturing solutions and commitment to quality. With a legacy spanning over a century, Mazak has established itself as a leader in the production of advanced machine tools that cater to a diverse range of industries worldwide.

Business Type: Manufacturer of CNC machine tools and automation solutions

Headquarters: Oguchi, Aichi Prefecture, Japan

Main Markets: Global presence with significant markets in North America, Europe, and Asia

Establishment Year: 1919

Certificates/Awards: ISO 9001 certification, Queen’s Award for Export Achievement, and numerous industry accolades for innovation and quality

Mazak’s key strengths are highlighted by its extensive product range, which includes:

- Hybrid multi-tasking machines

- 5-axis machining centers

- CNC turning centers

- Laser processing machines

With 11 manufacturing plants worldwide—five in Japan and others in the U.S., U.K., Singapore, and China—Mazak achieves an impressive annual output of thousands of machines, all while upholding high standards of precision and quality. Their commitment to research and development has birthed innovations like the SMOOTH TECHNOLOGY control system, enhancing user experience and operational efficiency.

Moreover, Mazak prioritizes customer support through a network of over 83 technology and technical centers globally, ensuring prompt assistance and access to cutting-edge machining technologies. The iSMART Factory initiative exemplifies Mazak’s dedication to digital transformation, integrating smart technologies that boost productivity and lower operational costs.

Ultimately, Mazak provides unparalleled value with high-quality machine tools, innovative technologies, and comprehensive support. Their focus on continuous improvement positions them as a trusted partner for manufacturers seeking reliable CNC solutions that enhance operational efficiency and competitiveness.

Okuma Corporation

Okuma Corporation is a prestigious leader in the CNC milling machine industry, recognized for its commitment to innovation and quality. With a legacy that spans over a century, Okuma has established itself as a key player in the global market for machine tools, providing advanced solutions that enhance manufacturing efficiency and precision.

Business Type: Manufacturer of CNC machine tools and automation solutions

Headquarters: Ōguchi, Aichi Prefecture, Japan

Main Markets: Global presence with significant markets in North America, Europe, Asia, and Australia

Establishment Year: 1898

Certificates/Awards: ISO 9001 certification, numerous industry awards for innovation and excellence in manufacturing

Okuma’s key strengths lie in its comprehensive product range, which includes:

- CNC lathes

- Multitasking machines

- Vertical and horizontal machining centers

- Grinding machines

Operating multiple state-of-the-art production facilities worldwide, Okuma boasts an annual output of over 7,000 CNC devices and approximately 30,000 spindles and servo motors. This extensive capacity enables the company to meet the diverse needs of customers in industries such as automotive, aerospace, and general manufacturing.

Okuma’s unique “Single Source” philosophy allows it to design and manufacture all critical components—including CNC controls, drives, motors, and encoders—ensuring seamless integration and high performance.

At the forefront of technological innovation, Okuma has pioneered advancements like the OSP series of CNC controls, featuring absolute position feedback systems for enhanced accuracy. The company also develops cutting-edge technologies for thermal compensation and collision avoidance, significantly improving machining precision and safety. These innovations reflect Okuma’s dedication to continuous improvement and customer satisfaction.

Haas Automation

Haas Automation, Inc. is a leading manufacturer of CNC (Computer Numerical Control) machine tools, recognized for its commitment to quality and affordability in the machining industry. Established in 1983, Haas has grown to become one of the largest builders of CNC machines in the world, providing innovative solutions that cater to a wide range of manufacturing needs.

Business Type: Manufacturer of CNC machine tools and automation solutions

Headquarters: Oxnard, California, USA

Main Markets: Global presence with significant markets in North America, Europe, and Asia

Establishment Year: 1983

Certificates/Awards: ISO 9001 certification, ETL Listed mark for electrical standards compliance, and various industry accolades for innovation

Haas Automation excels with its extensive product line, including:

- Vertical machining centers (VMCs)

- Horizontal machining centers (HMCs)

- CNC lathes

- Rotary tables

- Specialty machines

Operating from a 1.3 million square foot state-of-the-art facility in Oxnard, California, Haas employs lean manufacturing techniques and just-in-time production to ensure high-quality output and efficiency. With an impressive annual production capacity of 20,000 machines, Haas meets the diverse demands of industries such as aerospace, automotive, medical, and electronics.

A standout feature of Haas products is their competitive pricing without sacrificing quality. The launch of the VF-1 vertical machining center in 1988 was a game-changer, being the first American-built VMC priced under $50,000. This commitment to affordability has made Haas machines accessible to both small and medium-sized enterprises as well as large manufacturers.

Moreover, Haas emphasizes user-friendly design and robust support. Their Next Generation Control (NGC) system enhances machine operation with advanced connectivity features, simplifying programming and monitoring.

Hurco Companies, Inc.

Hurco Companies, Inc. is a prominent manufacturer in the CNC (Computer Numerical Control) machine tool industry, specializing in innovative solutions that enhance productivity and efficiency for manufacturers worldwide. Established in 1968, Hurco has built a strong reputation for its advanced technology and user-friendly machining systems, making it a trusted partner for businesses seeking to optimize their manufacturing processes.

Business Type: Manufacturer of CNC machine tools and automation solutions

Headquarters: Indianapolis, Indiana, USA

Main Markets: North America, Europe, Asia

Establishment Year: 1968

Certificates/Awards: ISO 9001 certification, numerous industry awards for innovation and quality

Hurco’s key strengths are rooted in its commitment to cutting-edge technology and a diverse product range, including:

- Vertical machining centers

- CNC lathes

- Advanced control software

The company operates modern manufacturing facilities equipped with state-of-the-art technology, producing approximately 1,800 CNC machines annually. A standout feature is its proprietary WinMax control software, which enables both skilled and unskilled operators to program complex machining tasks efficiently. This software simplifies the programming process and integrates seamlessly with CAD/CAM systems, significantly reducing setup times and enhancing overall productivity.

In addition to innovative products, Hurco places a strong emphasis on customer support through a robust global distribution network spanning over 50 countries. This ensures customers have access to comprehensive service and training resources. Hurco invests around 5% of its total revenue in research and development, enhancing machine capabilities and introducing new technologies. Notable innovations include the UltiMotion motion control system, which reduces cycle times while improving surface finish quality.

Hurco Companies, Inc. distinguishes itself in the CNC milling machine market through its focus on innovation, high-quality products, and exceptional customer service. The ability to provide customizable solutions tailored to specific manufacturing needs positions Hurco as a valuable partner for businesses aiming to improve operational efficiency and competitiveness in a dynamic market environment. With a strong commitment to quality and technological advancement, Hurco continues to lead the way in the CNC machining industry.

SYIL

SYIL is a rapidly growing manufacturer of high-precision CNC machines, specializing in providing affordable solutions tailored to the needs of hobbyists, small businesses, and industrial manufacturers. Established in 2005, SYIL has quickly gained recognition in the CNC milling machine industry for its commitment to quality, innovation, and customer satisfaction.

Business Type: Manufacturer of CNC machine tools

Headquarters: Ningbo, Zhejiang Province, China

Main Markets: Global presence with significant markets in North America, Europe, Asia, and Australia

Establishment Year: 2005

Certificates/Awards: ISO 9001 certification and various industry awards for product excellence and innovation

SYIL excels with its diverse product rang, featuring compact CNC milling machines like the SYIL X5, X7, and X9 series. These machines are engineered for high precision and reliability, all while being affordable.

Operating from a modern facility in Ningbo, SYIL produces a variety of CNC machines tailored for applications ranging from intricate designs to large-scale productions. The company prioritizes high-end components from reputable suppliers such as Schneeberger, THK, and Siemens, ensuring exceptional performance.

“With an annual production capacity of several thousand units, SYIL meets the growing demands of its global customer base.”

In addition to quality, SYIL emphasizes user-friendly designs, making their machines accessible for both seasoned operators and newcomers. Advanced control systems enhance the user experience and operational efficiency. Notable innovations include epoxy granite frames in the X7 model, which significantly improve stability and precision.

SYIL’s commitment to customer support is evident through its global dealer network and responsive service capabilities.

Standing out in the CNC milling machine market, SYIL offers high-quality products at competitive prices without sacrificing performance or reliability. Their focus on continuous innovation and customer satisfaction positions them as a valuable partner for manufacturers seeking effective machining solutions.

“With a strong commitment to quality and an expanding international presence, SYIL is poised for continued growth in the CNC industry.”

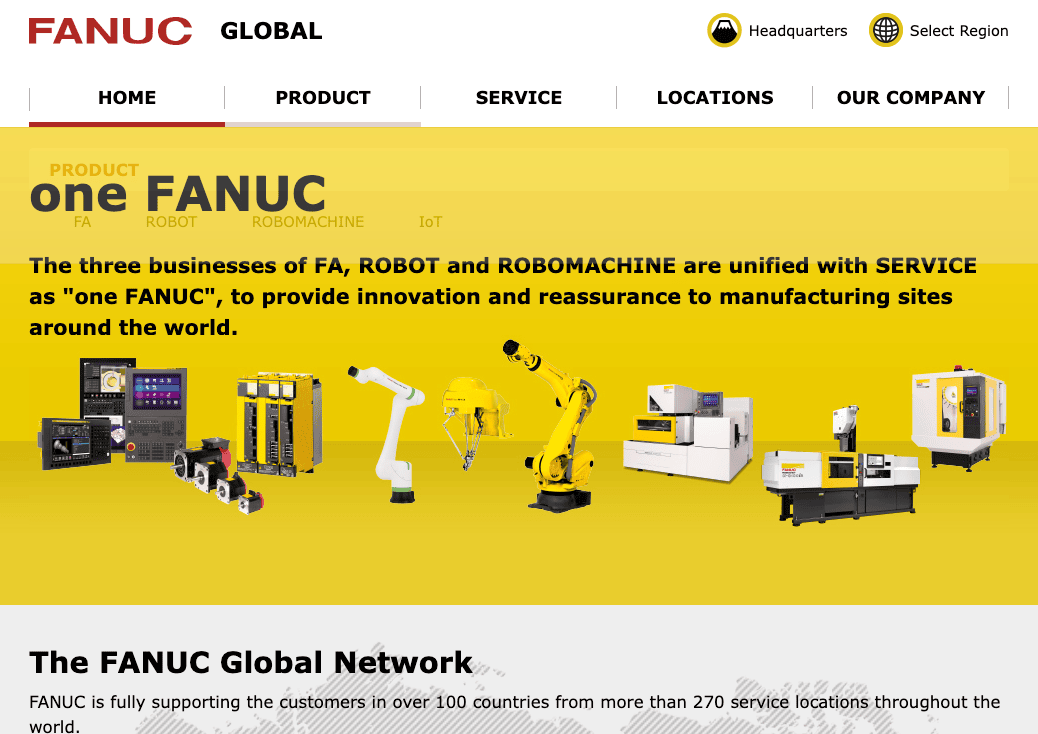

FANUC

FANUC Corporation is a global leader in factory automation, specializing in CNC (Computer Numerical Control) systems, robotics, and advanced manufacturing technologies. Founded in 1956, FANUC has established a strong presence in the industry by providing innovative solutions that enhance productivity and efficiency across various sectors, including automotive, aerospace, and electronics.

Business Type: Manufacturer of CNC systems, industrial robots, and automation solutions

Headquarters: Oshino-mura, Yamanashi Prefecture, Japan

Main Markets: Global presence with significant markets in Japan, North America, Europe, and Asia

Establishment Year: 1956

Certificates/Awards: ISO 9001 certification, various industry awards for innovation and excellence in automation technology

FANUC’s key strengths are rooted in its comprehensive product offerings and advanced technological capabilities. The company boasts multiple state-of-the-art manufacturing facilities that produce a diverse array of CNC machines and robotic systems. With over 40 million products installed worldwide, FANUC is celebrated for its high-quality CNC controls and servo motors, which power a significant portion of the world’s machine tools.

“Continuous innovation is at the heart of FANUC’s mission.”

Recent advancements include AI-driven technologies like AI Thermal Displacement Compensation and Cutting Load Monitor functions, which enhance machining precision and operational efficiency.

In addition to its robust product range, FANUC prioritizes exceptional customer support through a global service network, ensuring long-term reliability and maintenance. The company is also committed to sustainability and energy efficiency, developing solutions that minimize environmental impact while maximizing productivity. Notably, FANUC’s collaborative robots (cobots) are designed for ease of use and safety, enabling them to work alongside human operators without extensive programming.

FANUC delivers unparalleled value through its cutting-edge technology, extensive product range, and dedication to customer service. As a trusted partner in factory automation, it empowers manufacturers to achieve greater efficiency and productivity while addressing modern manufacturing challenges. With a strong focus on innovation and sustainability, FANUC is poised to shape the future of automation worldwide.

Mitsubishi Electric

Mitsubishi Electric Corporation is a global leader in the manufacturing of electrical and electronic products, including advanced CNC (Computer Numerical Control) systems. Established in 1921, the company has built a strong reputation for innovation and quality in various industries, including factory automation, aerospace, automotive, and electronics. Mitsubishi Electric’s CNC solutions are designed to enhance productivity and precision in manufacturing processes worldwide.

Business Type: Manufacturer of CNC systems, factory automation solutions, and electrical equipment

Headquarters: Chiyoda-ku, Tokyo, Japan

Main Markets: Global presence with significant markets in Asia, North America, Europe, and the Middle East

Establishment Year: 1921

Certificates/Awards: ISO 9001 certification, various awards for innovation in manufacturing technology

Mitsubishi Electric excels in advanced technology and a comprehensive product range. Their cutting-edge M800/M80 series features a CNC-dedicated CPU, significantly boosting processing speed and accuracy. With multiple manufacturing facilities in Japan and abroad, Mitsubishi Electric delivers high-quality CNC machines tailored for diverse machining applications.

“Their commitment to innovation is evident in their integration of IoT and AI technologies into their CNC systems.”

The M800/M80 series highlights Mitsubishi Electric’s focus on user experience with high-speed processing and enhanced operability. Key features include:

- Tool Center Point Control

- Inclined Surface Machining

- Wireless LAN capabilities for remote access and control

These innovations help manufacturers adapt to modern production demands while promoting sustainability. Mitsubishi Electric aligns its operations with an environmental vision for 2050, developing energy-efficient machines that minimize waste and reduce greenhouse gas emissions.

Mitsubishi Electric provides unparalleled value through innovative CNC solutions that merge advanced technology with quality and sustainability. Their extensive industry experience positions them as a trusted partner for manufacturers aiming to enhance operational efficiency amidst the challenges of contemporary production environments. With a commitment to continuous improvement and customer satisfaction, Mitsubishi Electric remains a leader in the CNC milling machine market.

Makino

Makino Milling Machine Co., Ltd., commonly known as Makino, is a renowned leader in the CNC (Computer Numerical Control) machine tool industry, specializing in high-precision machining solutions. Established in 1937, Makino has consistently been at the forefront of innovation, developing groundbreaking technologies that enhance manufacturing efficiency and quality across various sectors, including aerospace, automotive, and semiconductor industries.

Business Type: Manufacturer of CNC machine tools and automation solutions

Headquarters: Mason, Ohio, USA (originally founded in Japan)

Main Markets: Global presence with significant markets in Asia, North America, and Europe

Establishment Year: 1937

Certificates/Awards: ISO 9001 certification, numerous industry awards for innovation and excellence in machine tool manufacturing

Makino excels with its comprehensive product lineup and commitment to technological advancement. The company specializes in:

- Vertical Machining Centers (VMCs)

- Horizontal Machining Centers (HMCs)

- 5-Axis Machining Centers

- Electrical Discharge Machines (EDMs)

With manufacturing facilities in Japan and the USA, Makino produces high-quality machines for diverse applications. Recent investments, including a new plant in Wuhan, China, aim to boost annual output by 20%, demonstrating its dedication to meeting global demand for advanced machining solutions.

Among Makino’s notable innovations is the first high-speed spindle for milling, introduced in 1984, which transformed machining efficiency. The launch of Geometric Intelligence software in 1990 further established Makino as a pioneer in high-speed machining technology. The company’s focus on automation is exemplified by ATHENA, a voice-activated assistant that enhances operations and user interaction with CNC machines. These advancements not only improve productivity but also ensure exceptional precision and reliability.

Makino delivers unparalleled value through its cutting-edge technology, extensive product range, and unwavering commitment to customer satisfaction. With over 80 years of industry experience, Makino’s reputation for quality and innovation makes it a trusted partner for manufacturers seeking reliable CNC solutions that drive operational excellence. Its focus on continuous improvement positions Makino to effectively meet the evolving needs of modern manufacturing environments.

GF Machining Solutions

GF Machining Solutions is a premier provider of advanced manufacturing solutions, specializing in machines, automation systems, and services tailored for the precision machining industry. With a rich heritage that spans over 200 years, GF Machining Solutions has established itself as a leader in the field of CNC milling, electrical discharge machining (EDM), and laser technologies, serving customers in various sectors including automotive, aerospace, medical, and electronics.

Business Type: Manufacturer of CNC machine tools and automation solutions

Headquarters: Lincolnshire, Illinois, USA

Main Markets: Global presence with significant markets in Europe, North America, and Asia

Establishment Year: 1802 (as part of Georg Fischer Group)

Certificates/Awards: ISO 9001 certification, various industry awards for innovation and excellence in manufacturing technology

GF Machining Solutions excels with a comprehensive product portfolio and a commitment to innovation. Operating globally, its state-of-the-art milling center in Biel/Bienne, Switzerland, specializes in high-precision machines using advanced automation for efficiency and quality. Meeting global demand, their machines are renowned for accuracy and surface finish, making them ideal for complex tasks.

“Innovation is at the core, with technologies like rConnect for real-time monitoring and predictive maintenance.”

The company’s dedication to innovation is evident through technologies like rConnect, which offers real-time monitoring and predictive maintenance. Services include advanced diagnostics and tailored training via the GF Academy, maximizing technology investments.

GF Machining Solutions leads the CNC market with a diverse range, a commitment to quality, and sustainable practices, ensuring customer satisfaction and technological advancement. A trusted partner for high-performance solutions, it is poised to lead the industry into the future.

Comparison of Manufacturers

| Manufacturer | Key Products | Price Range | Specialties |

|---|---|---|---|

| DMG MORI | Multi-tasking machines | High | Aerospace, Automotive |

| Mazak | INTEGREX series | High | Multitasking |

| Okuma | Lathes, Machining centers | Medium-High | High rigidity |

| Haas Automation | Vertical/Horizontal Machining | Low-Medium | Cost-effective solutions |

| Hurco | Advanced 5-axis machines | Medium | Customization options |

| SYIL | Affordable milling machines | Low | Hobbyist-friendly |

| FANUC | Robotics & CNC systems | Medium-High | Automation |

| Mitsubishi Electric | High-performance CNC | Medium-High | Precision engineering |

| Makino | High-speed machining centers | High | Mold-making |

| GF Machining Solutions | Comprehensive machining solutions | Medium-High | Precision machining |

What is a CNC Milling Machine?

A CNC milling machine is a computer-controlled cutting tool used in manufacturing to precisely remove material from a workpiece, creating specific parts or products. This advanced technology combines traditional milling with computer numerical control (CNC) systems for highly accurate and efficient production of complex components.

Key Features of CNC Milling Machines

- Computer Control: Programmed using CAD and CAM software

- Subtractive Manufacturing: Removes material from a solid block

- Multi-Axis Capability: Operates on 3 to 5 axes for complex part production

How Does a CNC Milling Machine Work?

- Create a 3D CAD model of the desired part

- Convert the design into machine instructions (G-code)

- Set up the machine with tools and workpiece

- Execute the program for automated cutting

Components of a CNC Milling Machine

| Component | Function |

|---|---|

| Spindle | Holds and rotates cutting tools |

| Worktable | Secures the workpiece |

| Axes | Allow movement in different directions |

| Control panel | Interface for machine operation |

| Frame | Provides stability and houses components |

Advantages of CNC Milling

- High precision and consistency

- Complex 3D shape creation

- Material versatility (metals, plastics, composites)

- Increased efficiency and reduced labor costs

- Suitable for prototyping and high-volume production

Industries Using CNC Milling Machines

- Automotive

- Aerospace

- Medical device manufacturing

- Precision engineering

CNC milling machines have revolutionized modern manufacturing by enabling the production of sophisticated components with unparalleled accuracy and efficiency.

Conclusion

Choosing the right CNC milling machine manufacturer is vital for achieving operational excellence in manufacturing processes. The companies listed above represent the best options available in 2025, each offering unique strengths that cater to different industry needs. By considering factors such as product offerings, innovations, and market reputation, businesses can make informed decisions that align with their manufacturing goals.