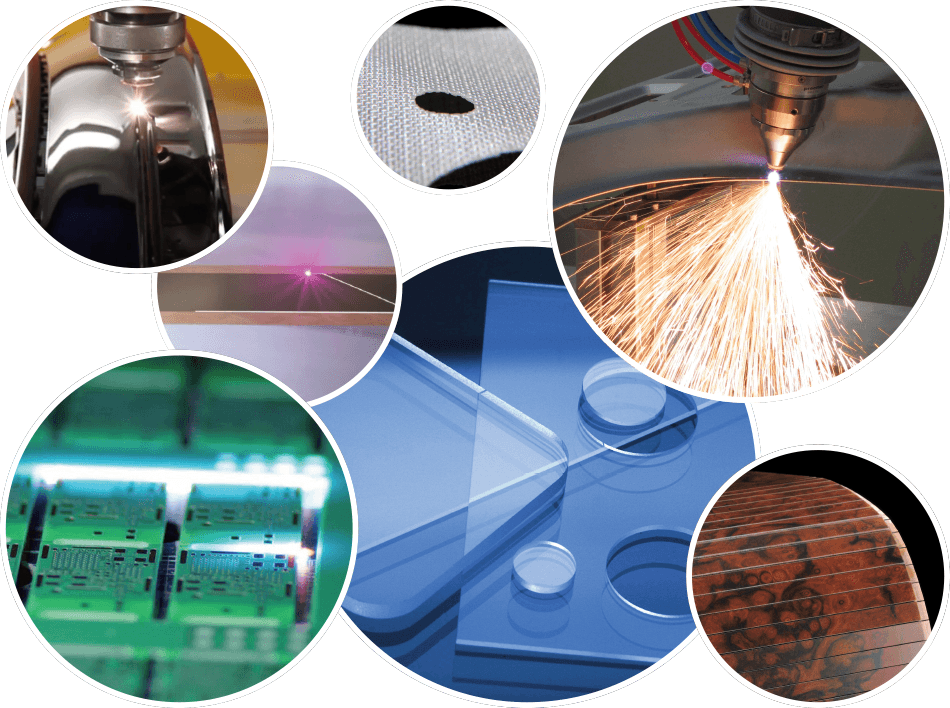

The manufacturing industry is undergoing a significant transformation with the emergence of advanced technologies, particularly in the field of laser welding. Among these innovations, 3 in 1 laser welding machines—which combine welding, cutting, and cleaning functions—are becoming increasingly popular due to their versatility and efficiency. However, before deciding to invest in these machines, it is essential to consider several factors to ensure optimal production processes and quality outcomes. In this article, we will highlight the top suppliers of 3 in 1 laser welding machines.

Overview

The global laser welding machine market is projected to grow significantly, driven by increasing demand across various sectors such as automotive, aerospace, electronics, and metal fabrication. According to recent market analyses, the laser welding equipment market is expected to reach approximately $4.58 billion by 2030, with a compound annual growth rate (CAGR) of around 5.5% from 2024 to 2030. This growth is attributed to the rising adoption of automation in manufacturing processes and the ongoing need for high-precision welding solutions.

Top 10 3 in 1 Laser Welding Machine Suppliers

Coherent

Coherent, Inc. stands as a global leader in the laser technology industry, recognized for its innovative solutions and extensive product offerings. With over five decades of experience, Coherent has established itself as a trusted supplier of advanced laser systems, particularly in the realm of welding technology.

Website: www.coherent.com

Business Type: Laser technology manufacturing and supply

Headquarters: Saxonburg, Pennsylvania, USA

Main Product: 3 in 1 Laser Welding Machines (ExactWeld series)

Main Markets: North America, Europe, Asia-Pacific

Establishment Year: 1966

Certificates/Awards: ISO 9001 Certification, various industry innovation awards

Coherent excels in the laser technology sector, specializing in 3 in 1 laser welding machines that integrate cutting, welding, and cleaning functions. This innovative approach caters to industries like automotive and medical device manufacturing, enhancing operational efficiency and precision.

The company boasts advanced manufacturing facilities worldwide, ensuring high production capacity and rapid service delivery. Coherent’s ExactWeld series is a testament to its commitment to quality and versatility, utilizing cutting-edge technologies such as fiber lasers and ultrashort pulse lasers to meet complex application demands.

Coherent prioritizes maintaining rigorous quality standards while offering competitive pricing. By focusing on sustainability and efficiency, the company positions itself as a reliable partner for businesses seeking innovative laser welding solutions. With extensive industry experience and a comprehensive range of high-performance products, Coherent stands out as a leader in the laser welding market.

Amada Weld Tech

Amada Weld Tech is a leading provider of advanced laser welding solutions, recognized for its innovative approach and extensive expertise in the field. As a subsidiary of the renowned Amada Group, Amada Weld Tech has established itself as a key player in the laser welding machine market, catering to a diverse range of industries globally.

Website: www.amadaweldtech.eu

Business Type: Development, design, production, and sales of laser welding equipment and systems.

Headquarters: Munich, Bavaria, Germany

Main Product: 3-in-1 Laser Welding Machines (Laser Welding, Laser Marking, and Laser Cutting Systems)

Main Markets: Automotive, Electronics, Medical Devices, Aerospace, and IT Industries.

Establishment Year: 1972

Certificates/Awards: ISO 9001:2015 Certification

Amada Weld Tech operates cutting-edge production facilities in Munich, Germany; Eindhoven, The Netherlands; and Cambridge, UK. These strategic locations empower the company to deliver high production capacity and exceptional service, ensuring prompt availability of premium-quality laser welding solutions to clients worldwide. With a dedicated workforce of over 800 professionals, Amada Weld Tech is committed to continuous innovation, enhancing the efficiency and precision of its laser welding systems to meet diverse industrial needs.

The company specializes in a comprehensive range of laser welding equipment, including versatile 3-in-1 laser welding machines that integrate cutting, marking, and welding functionalities. Additionally, Amada Weld Tech offers advanced solutions for resistance and micro-welding applications. By incorporating state-of-the-art technologies like Active Heat Control and IoT monitoring systems, the company maximizes operational efficiency and ensures optimal processing conditions for its customers.

Amada Weld Tech’s unique advantage lies in its tailored solutions that cater to individual client requirements. The company’s extensive expertise supports customers throughout the manufacturing process—from initial consultation to after-sales service—demonstrating a strong commitment to quality and sustainability. This customer-centric approach positions Amada Weld Tech as a reliable partner in the global laser welding market, providing innovative solutions that enhance productivity and drive success.

IPG Photonics

IPG Photonics Corporation is a global leader in high-performance fiber laser technology, renowned for its innovative solutions in laser welding and materials processing. The company has revolutionized the industry by providing advanced laser systems that enhance productivity, reduce operational costs, and improve product quality across various sectors.

Website: www.ipgphotonics.com

Business Type: Manufacturer of fiber lasers and amplifiers, specializing in laser welding systems

Headquarters: Marlborough, Massachusetts, USA

Main Product: 3-in-1 Laser Welding Machines (integrating welding, cleaning, and cutting capabilities)

Main Markets: North America, Europe, Asia-Pacific, and Latin America

Establishment Year: 1990

Certificates/Awards: ISO 9001 Certification, S&P 500 Index Member, multiple industry innovation awards

IPG Photonics is a leading manufacturer of advanced fiber laser solutions, specializing in versatile laser welding systems that cater to industries such as automotive, aerospace, electronics, and medical device manufacturing. With production facilities strategically located in the United States, Germany, Russia, and Italy, IPG ensures stringent quality control and rapid innovation cycles to meet market demands.

The company’s flagship offerings include the LightWELD handheld laser welding systems and the Laser Seam Stepper (LSS), both engineered for exceptional precision and user-friendly operation. The LightWELD system enables operators to achieve high-quality welds with minimal training due to its intuitive controls. Notably, IPG’s fiber lasers are recognized for their energy efficiency and low total cost of ownership, making them an ideal choice for manufacturers aiming to enhance productivity while reducing operational costs.

IPG Photonics provides unparalleled value through its innovative laser solutions that boost operational efficiency and uphold high-quality standards. The firm’s commitment to continuous research and development positions it at the forefront of laser technology advancements, equipping customers with cutting-edge tools necessary for success in a competitive landscape. By focusing on multi-functional laser welding machines, IPG meets diverse manufacturing needs while ensuring superior performance and reliability.

TRUMPF

TRUMPF is a leading global technology company renowned for its innovative solutions in laser technology and machine tools. With a strong commitment to advancing industrial manufacturing, TRUMPF stands out as a market leader, particularly in the realm of laser welding systems. The company has established itself as a pivotal player in the manufacturing sector, providing cutting-edge products and services that enhance productivity and precision across various industries.

Website: www.trumpf.com

Business Type: Manufacturer of laser technology and machine tools

Headquarters: Ditzingen, Baden-Württemberg, Germany

Main Product: TruLaser Weld series (3 in 1 Laser Welding Machines)

Main Markets: Europe, North America, Asia-Pacific

Establishment Year: 1923

Certificates/Awards: ISO 9001 Certification, German Innovation Award, Industry 4.0 Award

TRUMPF excels in laser technology, leveraging decades of expertise and substantial investments in research and development. With over 19,000 skilled professionals operating advanced manufacturing facilities globally, TRUMPF is committed to delivering high-quality laser welding solutions. The company’s production capabilities are enhanced by cutting-edge automation and a focus on sustainability, enabling it to efficiently meet the increasing demands of various industries.

TRUMPF offers a diverse range of products, including its renowned TruLaser Weld series, which integrates laser welding with cutting, punching, and bending functionalities. This adaptability allows TRUMPF to serve a wide array of sectors such as automotive, aerospace, and electronics. Their innovations in laser welding technology ensure exceptional precision and speed, particularly with complex welding applications that minimize workpiece distortion.

The company’s value proposition lies in its ability to provide reliable, high-performance solutions that significantly improve operational efficiency for clients. By embracing digital transformation and Industry 4.0 initiatives, TRUMPF positions itself at the forefront of manufacturing advancements. This commitment to innovation not only enhances product quality but also ensures that clients remain competitive in a rapidly evolving market landscape.

Han’s Laser

Han’s Laser Corporation is a leading global provider of advanced laser technology solutions, specializing in the design and manufacturing of laser welding machines, including their innovative 3-in-1 laser welding systems. Established in 1996, the company has grown to be recognized as a flagship in the laser industry, serving diverse markets across the globe.

Website: hanslaserus.com

Business Type: Manufacturer and supplier of industrial laser equipment

Headquarters: San Jose, California, USA

Main Product: 3-in-1 Laser Welding Machine (welding, cleaning, and cutting)

Main Markets: North America, Europe, Asia-Pacific

Establishment Year: 1996

Certificates/Awards: ISO 9001, ISO 14001, CE Certification, Ringier Technology Innovation Awards

Han’s Laser is a premier manufacturer of advanced laser solutions, specializing in 3-in-1 laser welding machines that integrate welding, cleaning, and cutting functionalities. With a strong commitment to innovation and quality, Han’s Laser has established itself as a leader in the laser technology sector, catering to various industries including automotive and electronics.

The company operates multiple state-of-the-art production facilities, ensuring high efficiency and precision in output. Their versatile product line includes multi-functional laser systems that utilize cutting-edge technologies such as intelligent CCD vision systems for accurate positioning and real-time feedback mechanisms to enhance consistency. Han’s Laser not only meets the growing demands of its global markets but also maintains rigorous quality control standards across all product offerings.

By offering high-quality equipment at competitive prices, Han’s Laser provides exceptional value to businesses seeking reliable laser solutions. Their ongoing investment in research and development ensures they remain at the forefront of technological advancements, making them the preferred choice for companies looking to improve productivity and efficiency in their operations.

Baison Laser

Baison Laser is a prominent player in the laser technology industry, specializing in the design and manufacturing of advanced laser welding machines. With a commitment to quality and innovation, Baison has established itself as a trusted supplier for businesses seeking reliable and efficient laser welding solutions.

Website: baisonlaser.com

Business Type: Manufacturer and Supplier of Laser Welding Machines

Headquarters: Foshan, Guangdong, China

Main Product: 3 in 1 Laser Welding Machines (Fiber Laser Welding, Cutting, and Marking)

Main Markets: Global markets including North America, Europe, Asia, and Australia

Establishment Year: 2003

Certificates/Awards: CE Certification, FDA Certification, ISO9001 Quality Management System Certification

Baison Laser has over 20 years of expertise in the laser welding industry, providing innovative solutions to clients across more than 100 countries. Our advanced manufacturing facility, covering 50,000 square meters, is equipped with cutting-edge technology and staffed by over 500 skilled professionals dedicated to producing high-quality laser systems.

Our extensive product lineup features versatile 3-in-1 laser welding machines, along with specialized equipment for cutting, cleaning, and marking. With a strong focus on research and development, we hold over 300 patents in laser technology, enabling us to adapt to the dynamic needs of sectors such as automotive, electronics, and metal fabrication.

Baison Laser’s unique value proposition lies in our ability to deliver customized solutions that meet specific customer requirements while maintaining competitive pricing. We prioritize quality assurance through rigorous testing and provide exceptional after-sales support to ensure client satisfaction. By integrating advanced technology with a customer-centric approach, Baison Laser is recognized as a leading supplier of laser welding equipment globally.

LaserStar Technologies

LaserStar Technologies is a leading manufacturer in the laser systems industry, specializing in high-precision laser welding, marking, and cutting solutions. Established in 1957, the company has built a strong reputation for delivering innovative and reliable laser technologies to meet the diverse needs of its global clientele.

Website: laserstar.net

Business Type: Manufacturer of laser systems and solutions

Headquarters: Orlando, Florida, United States

Main Product: Nd:YAG and Fiber Laser Welding Machines

Main Markets: North America, Europe, Asia-Pacific

Establishment Year: 1957

Certificates/Awards: ISO 9001 Certification, Various Industry Awards for Innovation and Quality

LaserStar Technologies excels in the laser technology sector, renowned for its high-quality laser welding solutions and exceptional customer service. With state-of-the-art manufacturing facilities located in Rhode Island, Florida, and California, the company efficiently produces advanced laser systems tailored to various industries, including automotive, aerospace, medical devices, jewelry, and electronics. As the only U.S. manufacturer of Nd:YAG micro welding systems, LaserStar is committed to continuous innovation and improvement, ensuring its products meet the evolving needs of clients.

The diverse product lineup includes 3-in-1 laser welding machines designed for both manual and semi-automatic operations, providing flexibility for different production environments. By integrating cutting-edge software solutions, LaserStar enhances operational efficiency, enabling precise and high-volume production. The company’s dedication to quality is reflected in its ISO 9001 certification and numerous industry awards, reinforcing its position as a leader in the laser welding market.

LaserStar Technologies’ unique value proposition lies in its ability to deliver tailored laser solutions backed by a knowledgeable technical support team available 24/7. This commitment to customer satisfaction ensures that clients receive personalized assistance with installation, training, and troubleshooting. By prioritizing client needs and maintaining open communication, LaserStar empowers businesses to boost productivity and achieve operational success with their advanced laser technologies.

KirinLaser

KirinLaser is a leading supplier in the laser technology sector, specializing in innovative solutions for industrial applications. With a decade of experience, the company has established itself as a trusted partner for businesses seeking advanced laser welding, cutting, and cleaning machinery. KirinLaser’s commitment to quality and customer satisfaction positions it prominently within the global market.

Website: kirinlaser.com

Business Type: B2B Wholesale Laser Machinery Supplier

Headquarters: Wuhan, Hubei, China

Main Product: 3-in-1 Laser Welding Machine (welding, cutting, and cleaning)

Main Markets: North America, Europe, Asia-Pacific

Establishment Year: 2014

Certificates/Awards: ISO 9001, ISO 14001, CE Certification

KirinLaser excels in the laser technology sector, providing cutting-edge laser welding solutions tailored for various industrial applications. With advanced manufacturing capabilities and a dedicated team, the company produces over 20,000 units annually, ensuring timely delivery and exceptional customer support.

KirinLaser’s product lineup features 3-in-1 laser welding machines that efficiently process materials like steel, stainless steel, and aluminum. These machines leverage AI-driven automation for enhanced performance and user-friendly operation, significantly reducing operational costs while maximizing precision. The company’s commitment to quality and competitive pricing makes it a premier choice for businesses seeking reliable laser technology solutions.

KirinLaser stands out through its focus on customizable solutions and comprehensive after-sales support, empowering clients to enhance their manufacturing capabilities safely and reliably. Whether serving small enterprises or large industrial clients, KirinLaser is dedicated to driving innovation in the laser welding market.

Senfeng Laser

Senfeng Laser Technology Co., Ltd. is a prominent player in the global laser machinery industry, specializing in the production of advanced laser welding machines and solutions. Founded in 2004 and headquartered in Jinan, China, Senfeng has established itself as a leader in providing innovative and efficient laser technology to meet the diverse needs of various manufacturing sectors worldwide.

Website: www.senfenglaserusa.com

Business Type: Manufacturer and Supplier of Laser Welding Machines

Headquarters: Jinan, Shandong, China

Main Product: 3-in-1 Laser Welding Machines (including handheld and automated models)

Main Markets: North America, Europe, Asia, Latin America

Establishment Year: 2004

Certificates/Awards: ISO 9001, CE Certification, FDA Certification, National Little Giant Enterprise Award

Senfeng Laser operates from an expansive 120,000 square meter facility, achieving an impressive annual output of over 50,000 laser welding machines. With a dedicated team of more than 1,000 skilled professionals focused on research and development, Senfeng ensures its products are at the forefront of technological advancements. Their versatile laser welding solutions are engineered to efficiently handle a variety of materials, including stainless steel, aluminum, and copper. Notably, Senfeng’s innovative designs enhance operational flexibility while reducing energy consumption by up to 90%, making them highly cost-effective for businesses.

The company is committed to maintaining high-quality standards throughout its rigorous manufacturing processes. Senfeng Laser has built a strong reputation for reliability and performance in the laser technology sector. Their customer-centric approach is reflected in their comprehensive after-sales support, which includes installation training and technical assistance across global service centers in the USA, Germany, India, Pakistan, and Serbia.

Senfeng Laser distinguishes itself through its extensive range of high-performance laser welding machines and its dedication to innovation and sustainability. By offering customized solutions tailored to specific customer requirements, Senfeng enhances productivity and operational efficiency in the manufacturing sector. Their strategic focus positions them as a trusted partner for businesses seeking advanced laser technology solutions that drive growth and efficiency.

Haiwei Laser

Haiwei Laser is a prominent player in the laser technology sector, specializing in advanced laser welding solutions. With a robust reputation built over 17 years, the company has established itself as a leader in the design and manufacturing of innovative laser welding machines, particularly known for its versatile 3 in 1 laser welding machines that cater to various industrial applications.

Website: www.haiweilaser.com

Business Type: Manufacturer and supplier of laser welding machines

Headquarters: Shenyang, Liaoning Province, China

Main Product: 3 in 1 Laser Welding Machines

Main Markets: Asia, Europe, North America

Establishment Year: 2006

Certificates/Awards: ISO9001:2015, ISO14001:2015, ISO45001:2018; numerous national patents

Haiwei Laser specializes in high-precision laser welding solutions, particularly its versatile 3 in 1 laser welding machines. These advanced systems are designed to meet the diverse needs of industries such as automotive, electronics, and metal processing. With state-of-the-art production facilities, Haiwei Laser boasts a robust annual output capacity that supports both large-scale manufacturing and customized projects, ensuring efficient service delivery to clients worldwide.

The company’s dedication to quality is underscored by its compliance with international standards and certifications, such as ISO9001:2015. Haiwei Laser’s products feature energy-efficient designs, user-friendly interfaces, and high-speed operation capabilities, which consistently exceed customer expectations. Significant investments in research and development enable the company to innovate continually, maintaining a competitive edge in the evolving laser technology market.

Haiwei Laser’s unique value proposition lies in its ability to provide cost-effective laser welding solutions tailored to client specifications. With extensive industry experience and advanced manufacturing capabilities, the company has established itself as a trusted partner for businesses seeking reliable laser welding technology. By integrating multiple functions—welding, cutting, and cleaning—into a single machine, Haiwei Laser enhances operational efficiency while minimizing production costs.

Comparison of 3 in 1 Laser Welding Machine Suppliers

| Supplier | Key Features | Price Range | Market Focus |

|---|---|---|---|

| Coherent | High precision, diverse applications | $10,000-$50,000 | Automotive, Medical |

| Amada Weld Tech | Custom solutions, robust technology | $15,000-$60,000 | Aerospace, Electronics |

| IPG Photonics | Innovative fiber lasers | $8,000-$40,000 | General Manufacturing |

| TRUMPF | Automated systems | $20,000-$100,000+ | Industrial Manufacturing |

| Han’s Laser | Handheld options | $5,000-$30,000 | General Manufacturing |

| Baison Laser | Customizable solutions | $4,000-$25,000 | Small to Medium Enterprises |

| LaserStar Technologies | Compact design | $3,500-$20,000 | Small Businesses |

| KirinLaser | Portable air-cooled systems | $5,500-$22,000 | Various Industries |

| Senfeng Laser | Comprehensive automation | $10,000-$50,000 | Industrial Automation |

| Haiwei Laser | High precision robotic systems | $7,000-$35,000 | Specialized Applications |

Conclusion

Choosing the right supplier for a 3 in 1 laser welding machine is essential for enhancing operational efficiency and maintaining product quality. The suppliers listed above represent some of the best options available in the market today. Each company brings unique strengths that cater to different manufacturing needs. As we continue to innovate within this space as a leading manufacturer ourselves, we remain committed to providing high-quality solutions that meet the evolving demands of our customers.